I first came across bonderized metal while helping a buddy put new siding on his garage. He kept saying it was “paint-ready,” and I had no clue what he meant.

I figured it was just regular steel with a fancy name. But after handling it and seeing how well the paint stuck, I got curious and looked into it more.

Turns out, bonderized steel has some neat features. It’s a type of galvanized steel with an extra treatment that makes it easier to paint and slows rust.

In this guide, I’ll break down what bonderized metal is, how it’s made, where you’ll see it used, and why some folks swear by it.

If you’re trying to figure out if it’s right for your project, I’ve got you covered.

What Is Bonderized Metal?

Bonderized metal is a type of galvanized steel, but it’s got a little more going on.

After the steel gets dipped in zinc, it’s treated with a phosphate coating. That coating gives it a dull gray finish and helps paint stick better.

The word “bonderized” actually started as a brand name, kind of like “Kleenex” for tissues.

U.S. Steel used it first, but now people just use it to describe this type of steel finish in general.

It’s often used where paint is going to be added later. Some people even call it “paint grip steel” because you don’t need to use a primer.

How is Bonderized Steel Made?

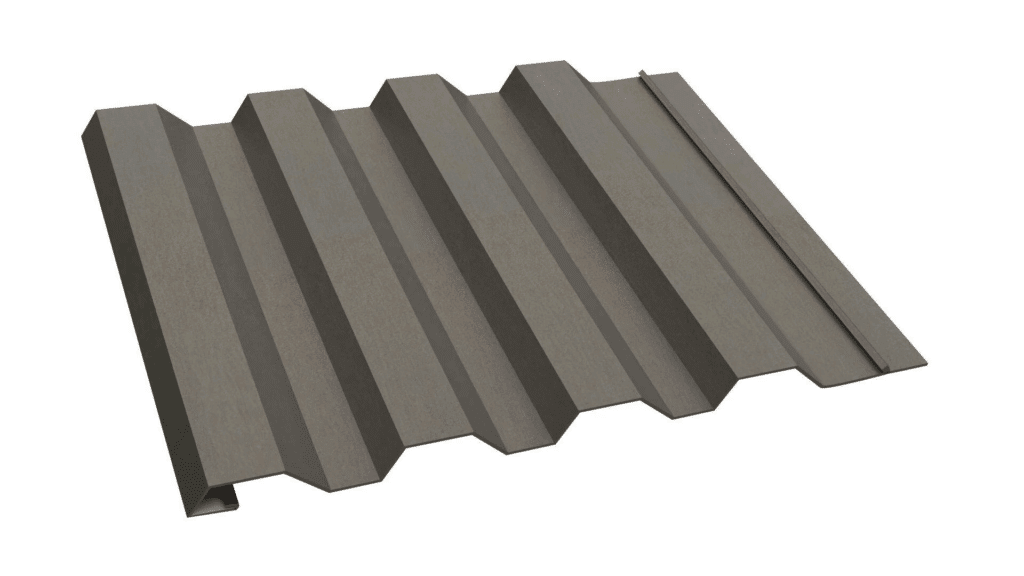

Bonderized steel is made using a process that starts much like regular galvanized steel.

First, the steel is cleaned and dipped in molten zinc. This gives it a protective layer that helps prevent rust.

Once it cools, the steel goes through a phosphate rinse. This rinse reacts with the zinc coating and creates a rough, dull surface.

After that, the steel is rinsed again and left to dry. What you get is a chalky, gray finish that feels a bit gritty to the touch.

That gritty texture is what makes bonderized steel paint-friendly. Paint sticks to it easily without needing a primer.

You can leave it unpainted for a while, but most people add a coat of paint for better protection and a cleaner finish.

Key Properties of Bonderized Steel

Bonderized steel is known for its unique properties that make it an ideal choice for many applications.

- Corrosion Resistance: The bonderized coating provides excellent protection against rust and environmental damage.

- Adhesion: It has a strong bond with various coatings, such as paint, making it versatile for finishing.

- Durability: Bonderized steel is highly durable and capable of withstanding harsh weather conditions and industrial environments.

- Smooth Surface: The process results in a smooth surface that is ideal for further coatings and finishes.

- Cost-Effective: It offers an affordable option for protective steel without the need for expensive coatings or treatments.

Common Applications of Bonderized Metal

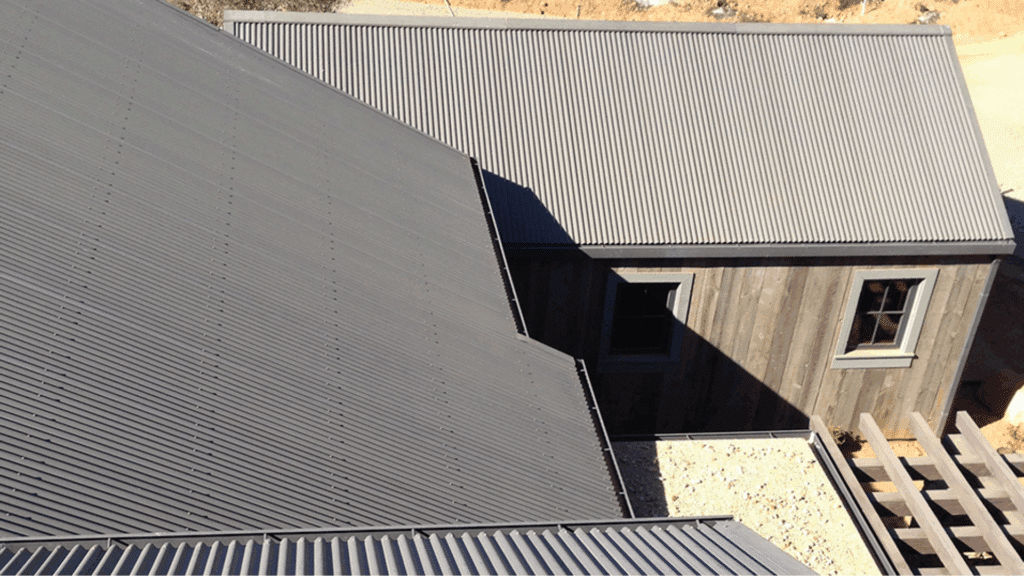

You’ll find bonderized metal in both homes and commercial buildings. It’s pretty versatile. Some common uses include

| Application Area | Common Uses |

|---|---|

| Residential & Commercial Builds | Roofing and siding panels |

| Exterior Drainage Systems | Gutters, flashings, and downspouts |

| HVAC Systems | HVAC ductwork |

| Structural & Trim Work | Wall trims and framing |

| Interior Design | Industrial-style interior accents |

| Outdoor Fixtures | Garage doors and fences |

| Industrial/Automotive | Select car parts and machinery components |

Some car parts and machinery also use it, but it’s more popular in buildings.

Benefits of Using Bonderized Metal

From the jobs I’ve worked on and the contractors I’ve talked to, bonderized has a solid list of perks

- No primer needed before painting

- Paint goes on smooth and holds tight

- Less prep time than other metals

- Stands up well to moisture once painted

- Costs less than stainless or powder-coated steel

It’s a nice middle ground if you want durability and a paintable surface.

Limitations and Things to Know

But let’s be real, bonderized metal isn’t perfect. Here’s what you should be aware of

- Don’t leave it bare too long or it may spot or rust

- Surface can be uneven or cloudy in places

- Chalky texture can rub off onto hands or tools

- Short shelf life if stored in damp places

So, paint it soon after installing or store it somewhere dry.

Bonderized vs Galvanized vs Galvalume: What’s the Difference?

Here’s a side-by-side look to compare these types easily.

| Feature | Bonderized | Galvanized | Galvalume |

|---|---|---|---|

| Coating | Zinc plus phosphate | Zinc only | Zinc plus aluminum mix |

| Appearance | Matte gray | Bright silver | Smooth, spangled |

| Paintability | Excellent | Needs primer | Hard to paint |

| Rust resistance | Good if painted | Moderate | Very good |

| Best Use | Painted jobs | Exposed metalwork | Bare finish roofing |

Use bonderized when you plan to paint. Go galvanized if you just want zinc protection. Use Galvalume for high-rust areas where painting isn’t needed.

Does Bonderized Steel Rust?

Yes, it can eventually.

The zinc coating helps stop rust, and the phosphate slows it even more. But if you leave it unpainted in wet weather, it’ll start to corrode.

That’s why painting is key. Once it’s sealed with paint, it holds up well for years.

How to Paint Bonderized Steel?

Painting bonderized steel is pretty straightforward, and from experience, it holds up well when properly prepped.

For example, I painted a trim piece on a backyard shed last year. Even after a rough winter and some strong summer sun, it still looks solid.

1. Clean the Surface: The first thing I did was wipe down the surface with a dry cloth to remove the chalky layer that naturally forms on bonderized metal. This step is crucial for making sure the paint sticks properly.

2. Primer or Not? One of the best things about bonderized steel is that you usually don’t need a primer. This saves a step in the process and helps get the job done quicker.

3. Choose the Paint: I used an acrylic paint, but oil-based paint works fine too if that’s what you have available. Both options perform well on bonderized steel.

4. Brushing vs. Spraying: I tried both brushing and spraying the paint. Both methods worked, though spraying gave a smoother finish. It’s a personal preference, depending on what you have and how you like to work.

5. Let Each Coat Dry: It’s important to let each coat dry completely before adding the next one. Taking your time during this step helps the paint last longer and prevents peeling or cracking down the road.

By following these steps, bonderized steel will get a smooth, durable finish that stands up to the elements.

Where to Buy Bonderized Metal

You can get bonderized sheets from these suppliers

- Western States Metal Roofing

- Industrial Metal Supply

- Team Pacesetter

- Metal Supermarkets

Look for

- Sheets or coils

- 24 to 26 gauge thickness

- 4×8 or 4×10 foot sizes

Some places can cut to size if you ask.

Safety and Maintenance Tips

If you’re planning to work with bonderized metal yourself, it’s good to know a few safety basics and care tips.

- Wear gloves because the surface can feel gritty

- Store it dry to prevent surface spotting

- Use metal snips or a fine-tooth blade when cutting

- Seal any cut edges with paint or sealant

- Wash it with water and mild soap

- Avoid harsh cleaners or pressure washers

- Touch up any scratches or dings quickly

- Keep bare pieces away from moisture

Taking a few simple steps during installation and afterward keeps bonderized metal in good shape.

It doesn’t demand much, but ignoring those small things can lead to problems down the line. A little attention now saves work later.

Conclusion

If you were wondering what bonderized metal is and whether it’s the right choice for your project, I hope this article gave you a clear answer.

It’s a great pick when you need a surface that’s ready for paint, and it holds up well when taken care of. I’ve used it myself and seen how much easier it makes certain jobs.

Now that you know how it’s made, where it’s used, and what to expect, you should feel good about deciding if it fits your needs.

No matter if you’re working on a shed, a roof, or a modern wall panel, bonderized could be just the thing you’re looking for.

Let me know if you want help choosing between it and other metals. I’ve been down that road too.

Frequently Asked Questions

Can Bonderized Metal Be Left Unpainted?

Yes, but only for a short time. It’s not designed to stay bare long-term in wet or coastal areas. For best results, it should be painted to protect against corrosion.

Do I Need to Use a Primer when Painting Bonderized Steel?

In most cases, no. The phosphate coating helps paint stick well without primer. Just make sure to clean the surface before painting.

Is Bonderized Metal Safe for Indoor Use?

Yes. It’s commonly used for interior design elements like wall panels, trims, and industrial-style accents. Just be sure to clean it before use indoors.

How Long Does Bonderized Metal Last?

If painted and maintained properly, it can last for decades. Unpainted pieces may start to degrade faster if exposed to constant moisture.

Can I Weld Bonderized Metal?

Yes, but it’s best to grind away the coating at the weld point first. After welding, clean and seal the area to prevent rust.