Choosing between Galvalume and Galvanized steel can be confusing. The differences aren’t always easy to spot, but selecting the right one can make a big difference in how long your project lasts.

If you’re unsure, you’re not alone. I’ve put together this guide to help simplify things. I’ll explain how each type is made, how they handle rust, heat, and moisture, and which one holds up better over time.

You’ll also find a handy comparison table, practical tips, and real-world examples to help you make an informed choice.

Let’s break it all down step by step so you can confidently choose the best option for your project.

Getting to Know Galvalume and Galvanized Steel

Before choosing the right steel, it helps to understand what Galvalume and Galvanized really are. Let’s break down their key features so you know what makes each one unique.

What Is Galvalume?

Galvalume is a protective coating made from aluminium, zinc, and a small amount of silicon. It’s applied to steel using a hot-dip process where the metal is dipped into a bath of the molten mixture.

The aluminum forms a strong outer layer that helps block long-term rust. Zinc adds extra protection by guarding the steel if it gets scratched or cut. Silicon helps the coating stick well to the surface.

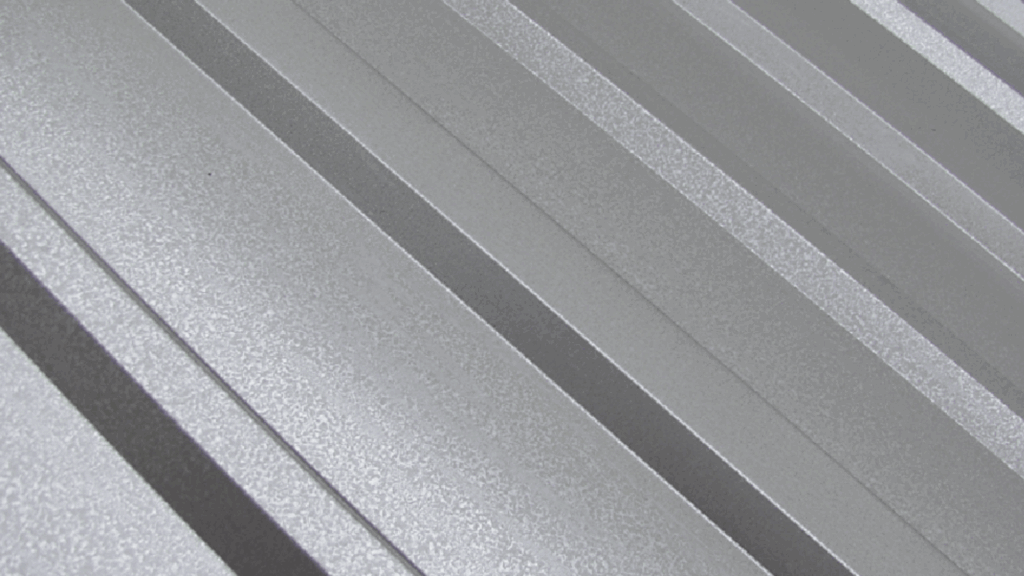

Galvalume is known for its excellent rust resistance, especially in coastal, humid, or harsh outdoor areas. It’s a popular choice for roofing, siding, barns, and metal buildings.

What Is Galvanized?

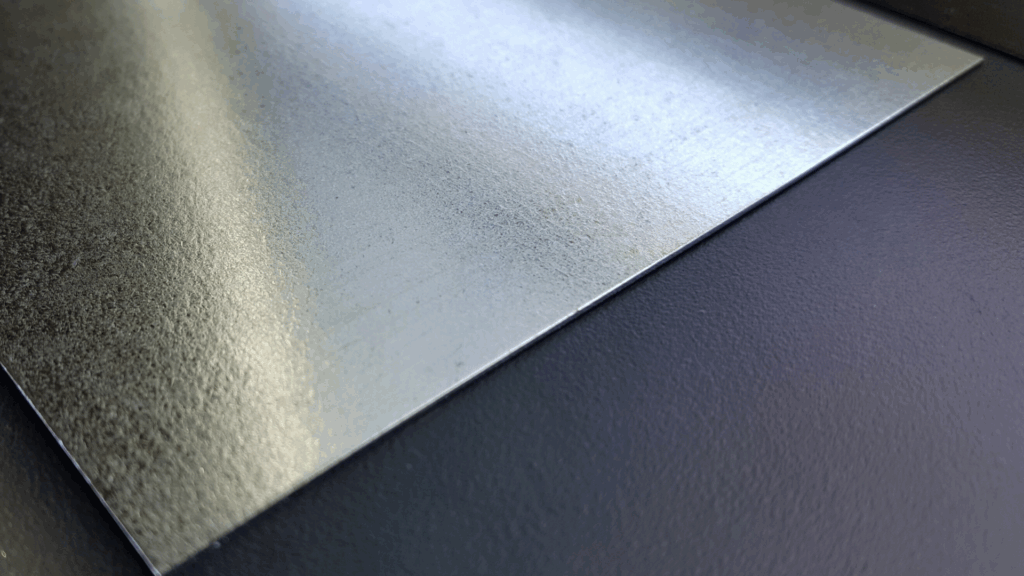

Galvanized steel is coated with a layer of pure zinc. This coating is added through a hot-dip process, where the steel is dipped into melted zinc.

The zinc acts like a shield, protecting the steel from air, water, and rust. If the surface gets scratched, the zinc still helps protect the steel underneath. This is called “sacrificial protection.”

Galvanized steel works well in dry or mild areas. It’s often used for fences, buckets, car parts, and indoor frames. It’s also a more affordable option for many projects.

Galvalume vs Galvanized: A Closer Comparison

Understanding how each material is made and performs will guide you in selecting the right one for your project.

1. Composition Breakdown

Understanding what each coating is made up of and how it’s applied helps explain the differences in durability and performance.

Galvalume is covered in a mix of aluminum, zinc, and a bit of silicon. This blend makes it super strong against rust.

The aluminum improves long-term protection, while zinc handles surface scratches.

Galvanized steel is coated with a layer of pure zinc. The zinc forms a protective barrier that helps prevent rust and corrosion.

This coating is simple but effective, especially in low-moisture settings.

2. Manufacturing Process

Both Galvalume and Galvanized steel are made by dipping the metal into a hot liquid bath. The only difference is what’s in that bath.

Galvalume uses a mix, while Galvanized Steel uses just zinc. The method is the same, but the materials change the performance.

After cooling, the coating bonds tightly to the steel, forming a protective layer.

3. Performance in Real Conditions

Galvalume is made for long-term durability. It resists rust even in coastal, humid, or rainy environments.

In tough outdoor settings, it can last two to four times longer than galvanized steel. It also reflects heat well, which helps keep buildings cooler.

Galvanized steel performs well in dry or mild conditions. It offers strong protection for indoor use or short-term outdoor projects.

However, it can rust faster when exposed to salty air or constant moisture, so it’s not ideal for coastal areas.

4. Best Uses

Galvalume Steel:

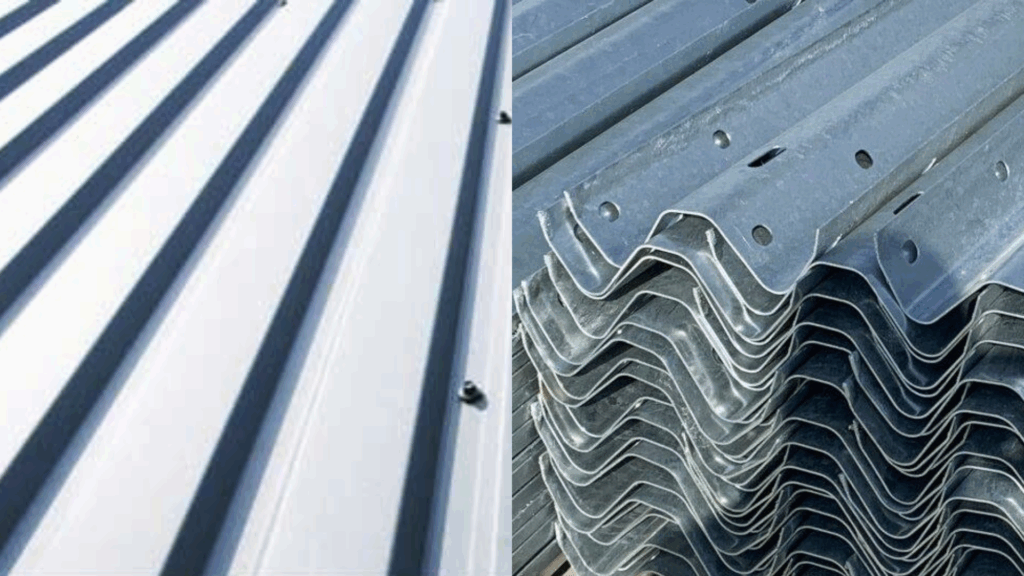

- Best for roofs, wall panels, barns, and metal buildings

- Works great in coastal, humid, or industrial areas

- Ideal when you want long life with little maintenance

Galvanized Steel:

- Great for fences, indoor beams, car parts, and farm tools

- Used in places that stay dry or aren’t exposed to salt or rain

- Good choice when cost is a bigger concern than long-term durability

Now that you know how each type works, look at this quick table to help you compare Galvalume Steel vs. Galvanized Steel at a glance.

Galvalume vs. Galvanized Steel: Quick Comparison

| Feature | Galvalume | Galvanized |

|---|---|---|

| Look | Smooth, dull silver finish | Shiny with a spangled pattern |

| Rust Protection | Strong and long-lasting | Good, but wears faster |

| Durability | Great in harsh weather | Works well, but not as long |

| Humidity Use | Great in wet or coastal areas | Not ideal near saltwater |

| Heat Resistance | Handles heat better | Coating may wear off |

| Common Uses | Roofs, walls, barns, near ocean | Fences, buckets, car parts |

| Cost | Costs a bit more | Cheaper option |

| Lifespan | 2–4x longer outdoors | Shorter life outside |

| Bendability | Harder to bend; coating may crack | Easy to bend and shape |

| Scratch Resistance | Okay, coating may expose metal | Good, zinc protects scratches |

| Maintenance | Low maintenance | Needs more upkeep |

This quick comparison should help you choose the steel that fits your project best.

Galvalume vs. Galvanized: Pros and Cons

Let’s take a quick look at the pros and cons of Galvalume and Galvanized steel, so you can compare them easily and make a faster decision.

| Feature | Galvalume Steel | Galvanized Steel |

|---|---|---|

| Pros | • Excellent rust resistance, even in coastal/humid areas • Long lifespan (2–4x longer outdoors) • Reflects heat well, great for energy savings • Low maintenance over time • Sleek, modern matte finish |

• Lower upfront cost • Easy to find and widely available • Easier to bend and shape • Good short-term rust protection • Works well for indoor and dry outdoor use |

| Cons | • Higher initial cost • Coating may crack if bent too much • Not ideal for applications needing lots of bending/shaping • May react with copper or lead if mixed |

• Rusts faster in salty or wet areas • Needs more frequent maintenance • Shorter lifespan outdoors • Can look patchy or spangled (aesthetic concern) |

Now that you’ve seen the pros and cons side by side, it should be easier to choose the steel that fits your project, budget, and environment best.

Galvalume Maintenance Tips

Want your Galvalume to last even longer? These easy care tips can help.

- Wash with water or mild soap to remove grime and salt

- Keep leaves, branches, or debris from collecting on the surface

- Avoid cutting or drilling after installation to reduce coating damage

- Inspect every few months for wear, especially in coastal areas

- Do not mix with copper or lead materials, which can react with the coating

- Choose fasteners that are Galvalume-compatible to avoid corrosion issues

With just a little upkeep, your Galvalume can stay strong and rust-free for years.

Galvanized Maintenance Tips

Galvanized steel needs a bit more care. Here’s how to keep it in great shape.

- Rinse the surface regularly to remove dirt and dust buildup

- Avoid letting it sit in wet or salty areas for a long period

- Touch up scratches or chips with zinc-rich paint to prevent rust

- Check for signs of rust or peeling and repair quickly

- Store away from dissimilar metals to prevent corrosion from contact

- Avoid harsh chemicals or pressure washing that can damage the coating

Regular checks and small fixes can help your galvanized metal last much longer.

Final Thoughts

You’ve now learned the key differences between Galvalume and Galvanized steel. From how they’re made to how they handle rust, heat, and moisture, this guide gives you the facts in a simple way.

You also saw where each type works best, how much care they need, and how long they last. This makes it easier to match the right material to your weather, project, and budget.

Galvalume is great for long-lasting outdoor use, while Galvanized is a good choice when you need something strong and more affordable.

Now that you have the full picture, take what you’ve learned and choose the metal that fits your needs best. I hope this helps you make a decision that will make your project last, look great, and stay strong for years to come.

Frequently Asked Questions

Can you paint over Galvalume or Galvanized steel?

Yes, but you need proper preparation. Galvanized steel is easier to paint with the right primer. Galvalume can be painted, too, but it may need special surface treatment to help the paint stick.

Is Galvalume safe for use with treated wood?

No. Galvalume should not touch pressure-treated or chemically treated wood. The chemicals can react with the coating and cause corrosion. Use a protective barrier or choose galvanized if contact is unavoidable.

Which one is better for DIY projects?

Galvanized steel is easier to cut, bend, and handle, making it better for most DIY jobs. Galvalume is tougher to work with and usually better for professional installations.

Can I use both materials on the same building?

It’s not recommended. Mixing metals can lead to galvanic corrosion, especially if they touch or share fasteners. Stick to one type throughout or use proper isolation materials between them.

Does Galvalume always outperform Galvanized?

Not always. Galvalume is better in harsh, wet, or coastal areas. But in dry, mild settings, galvanized steel performs just fine and costs less. Choose based on your specific conditions, not just lifespan alone.