Understanding wheel bolt patterns is crucial for safety and performance in vehicle modifications and maintenance.

The 5×142 bolt pattern, though less common than some alternatives, has carved out an important niche in the automotive world, particularly in Ford vehicles and performance applications.

This configuration, featuring five lug holes arranged in a 142mm diameter circle, offers exceptional structural integrity and versatility.

If you’re a car enthusiast looking to upgrade your wheels, a mechanic working on Ford F-150s, or simply someone wanting to understand vehicle specifications better, grasping the nuances of the 5×142 bolt pattern is essential for making informed decisions about wheel selection and installation.

Overview of the 5×142 Bolt Pattern

The 5×142 bolt pattern represents a specific wheel mounting configuration where “5” indicates the number of lug holes, and “142” represents the diameter in millimeters of the circle formed by the centers of these holes.

This pattern requires precise measurement and understanding for proper fitment, as even small variations can affect wheel installation and vehicle performance.

When measuring a 5-lug pattern, measuring from the center of any lug hole to the outer edge of the hole across from it (not center to center like with even-numbered patterns) is crucial.

This measurement ensures proper wheel mounting and maintains optimal vehicle safety and performance characteristics.

Evolution and Uses of 5×142 Bolt Pattern

The 5×142 bolt pattern emerged as manufacturers sought to optimize wheel mounting configurations for specific vehicle applications and load requirements.

This pattern has become particularly prevalent in certain European vehicle markets, offering a balance between structural integrity and weight distribution.

While less common than patterns like 5×114.3 or 5×112, the 5×142 configuration has carved out its niche in the automotive industry, particularly in performance-oriented vehicles and certain luxury models.

The pattern’s evolution reflects the automotive industry’s ongoing efforts to enhance vehicle handling characteristics while maintaining safety standards and meeting specific regional market requirements.

Key Considerations for 5×142 Wheels

When selecting wheels with a 5×142 bolt pattern, several critical factors demand attention beyond just matching the bolt pattern.

The hub center bore measurement is crucial for proper fitment, as an incorrect size can lead to vibration and handling issues.

Wheel offset plays a vital role in determining tire clearance and handling characteristics – positive offset moves the mounting face toward the wheel’s outer edge. In contrast, a negative offset moves it toward the inner edge.

Additionally, consider the wheel’s load rating to ensure it meets your vehicle’s requirements. The material choice between alloy and steel wheels affects performance and looks, while proper torque specifications must be followed during installation.

Why Choose a 5×142 Bolt Pattern

The 5×142 bolt pattern configuration offers distinct advantages for specific vehicle applications. The spacing between lug holes provides optimal load distribution, making it particularly suitable for vehicles that require enhanced stability and durability.

This pattern’s design helps reduce stress concentration around the hub area, potentially extending the lifespan of both wheels and related components.

The 5×142 pattern offers excellent structural integrity for performance-oriented vehicles while maintaining reasonable weight characteristics.

The configuration also provides good brake clearance for many vehicle models, making it compatible with various brake system upgrades and performance modifications.

Steps to Install 5×142 Wheels

Installing wheels with a 5×142 bolt pattern requires careful attention to detail and proper safety procedures.

Follow these essential steps to ensure a secure and proper installation that maximizes safety and performance.

The process can be broken down into four phases, each critical for ensuring proper wheel fitment and vehicle safety.

1. Preparation and Safety Check

Before beginning installation, ensure you have all the necessary tools, including a torque wrench, jack stands, and wheel chocks.

Position the vehicle on a level surface and engage the parking brake. Remove any wheel covers or hub caps and slightly loosen the lug nuts while the wheel is still on the ground.

2. Lifting and Removing

Use proper lifting points to raise the vehicle with a jack and secure it with jack stands. Never work under a car supported only by a jack.

Remove the lug nuts completely and carefully pull the old wheel straight off the hub to avoid damaging the studs.

3. Mounting New Wheels

Clean the mounting surface of both the wheel and hub, removing any rust or debris. Carefully lift the new wheel into position, aligning the bolt holes with the wheel studs.

Install the lug nuts by hand initially, ensuring they thread easily to avoid cross-threading.

4. Final Tightening and Verification

Lower the vehicle until the wheel touches the ground but still carries minimal weight. Tighten the lug nuts in a star pattern to ensure even pressure distribution, following the manufacturer’s torque specifications.

After installing, lower the vehicle fully and perform a final torque check.

Bolt Pattern Installation Mistakes to Avoid

Common installation errors can compromise both safety and performance when mounting 5×142 wheels.

A critical mistake is improper torque application – overtightening can stretch or break wheel studs, while under-tightening may lead to wheel loosening during operation.

Failing to clean mounting surfaces properly can result in uneven seating and vibration issues.

Another significant error is not following the correct tightening sequence, which can cause warping of brake rotors and uneven pressure distribution.

Always verify wheel fitment specifications before installation and avoid using impact wrenches for final tightening, as they can lead to inconsistent torque values and potential damage.

Converting a Vehicle to a 5×142 Bolt Pattern

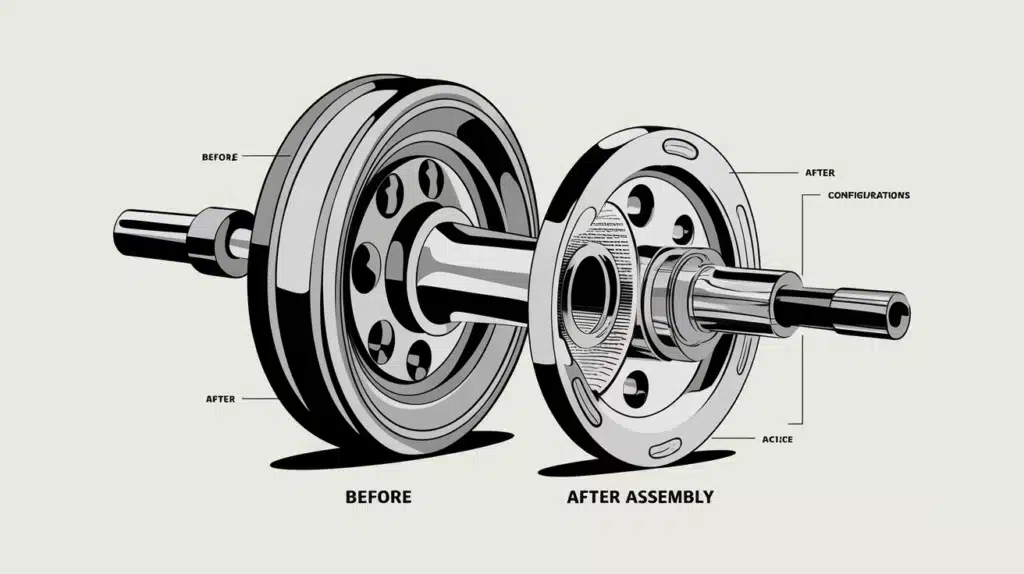

Converting a vehicle to a 5×142 bolt pattern requires careful planning and precise execution. The process typically involves replacing the hub assembly or installing wheel adapters designed specifically for this conversion.

When using adapters, ensure they’re high-quality and rated for your vehicle’s weight and intended use. Essential tools include a hub puller, torque wrench, and specialized measuring equipment to verify fitment.

Before conversion, consider factors like brake caliper clearance, suspension geometry, and wheel offset changes. It’s crucial to maintain proper wheel bearing preload during the conversion process.

Professional installation is recommended due to the complexity and safety implications of modifying crucial suspension components.

Popular Applications of 5×142 Bolt Pattern

The 5×142 bolt pattern has found its way into various automotive applications, each chosen for specific performance and durability requirements.

Understanding these applications helps illustrate why this particular pattern has become increasingly important in certain vehicle segments.

Let’s explore the main categories where this bolt pattern has significantly impacted.

1. Performance Vehicles

Several high-performance vehicles utilize the 5×142 bolt pattern, particularly in European models, where this configuration has gained popularity.

This pattern is often found in vehicles designed for enhanced handling and stability at higher speeds, as it provides excellent load distribution and structural integrity for performance applications.

2. Off-Road Applications

The 5×142 pattern has found significant use in off-road vehicles and SUVs where durability is paramount.

The spacing between lug holes provides optimal strength for handling the additional stresses of off-road driving while maintaining compatibility with a wide range of aftermarket wheel options designed for rugged terrain.

3. Commercial and Fleet Vehicles

Due to its reliability and load-bearing capabilities, commercial vehicles and fleet applications have adopted the 5×142 pattern.

This pattern’s design helps distribute weight evenly across the hub assembly, making it suitable for vehicles that regularly carry heavy loads or operate under demanding conditions.

Benefits of Using a 5×142 Bolt Pattern

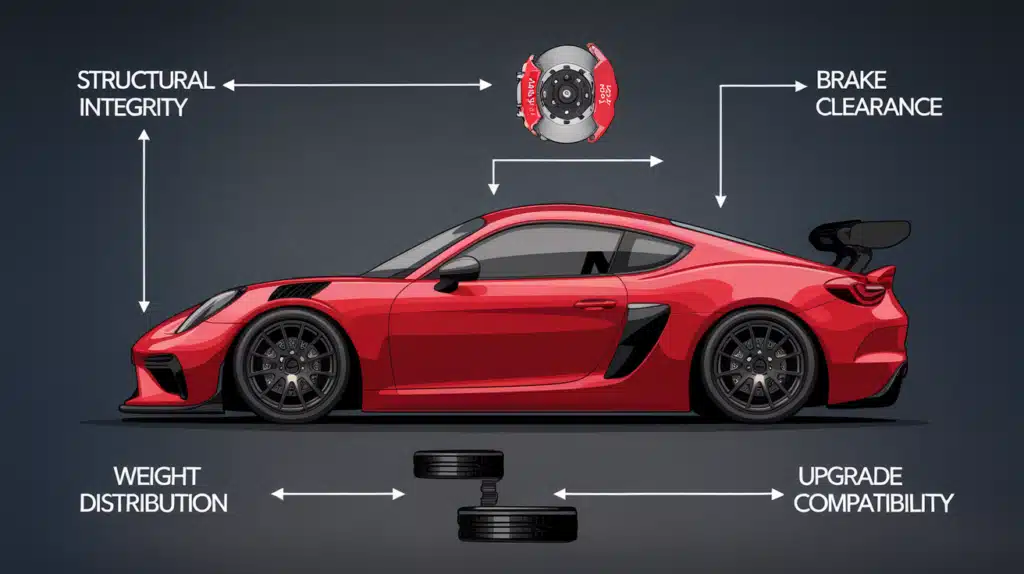

1. Enhanced Structural Integrity

The 5×142 bolt pattern offers superior structural strength due to its optimal lug spacing. This configuration helps distribute forces evenly across the wheel hub, reducing stress concentration and potential failure points.

The larger diameter pattern also provides better leverage for the lug nuts, ensuring more secure wheel attachment under various driving conditions.

2. Improved Brake Clearance

One significant advantage of the 5×142 pattern is its increased space for brake components.

This extra clearance allows for the installation of larger brake rotors and calipers, enhancing stopping power and heat dissipation.

Performance enthusiasts particularly appreciate this aspect when upgrading their vehicle’s braking system.

3. Better Weight Distribution

The symmetrical design of the 5×142 pattern contributes to better overall weight distribution across the wheel assembly.

This balanced configuration helps reduce vibration and promotes even tire wear, potentially extending the lifespan of both tires and suspension components.

4. Compatibility with Performance Upgrades

The 5×142 pattern is compatible with various performance upgrades and aftermarket modifications.

Its widespread use in certain vehicle segments has led to a strong selection of performance wheels and related components, giving owners more options for customization while maintaining safety and reliability standards.

Vehicles That Use the 5×142 Bolt Pattern

The 5×142 bolt pattern is primarily associated with modern Ford vehicles and other manufacturers adopting this specification.

This unique bolt pattern features five lug nuts arranged in a circle with a diameter of 142mm, offering a dependable and secure wheel mounting solution.

While less common than patterns like 5×114.3 or 5×120, the 5×142 configuration has gained prominence recently, particularly in heavy-duty applications and performance-oriented vehicles.

Its growing popularity can be attributed to its excellent load-bearing capabilities and compatibility with various wheel options.

1. Ford F-150 (2004-2014)

- Equipped with 5×142 bolt pattern across all trim levels

- Factory wheel sizes range from 17 to 22 inches

- Compatible with both steel and alloy wheel options

- Typical torque specifications: 150–165 ft-lbs

2. Ford Expedition (2003-2014)

- Features 5×142 bolt pattern standard on all models

- Accommodates wheel sizes from 17 to 20 inches

- Hub center bore diameter of 87.1mm

- Enhanced load capacity suitable for SUV applications

3. Ford Raptor (2010-2014)

- Purpose-built off-road performance truck utilizing a 5×142 pattern

- Specialized beadlock-capable wheels available

- Designed for extreme terrain capabilities

- Factory-recommended wheel width: 8.5 to 9.5 inches

4. Lincoln Navigator (2003-2014)

- Shares 5×142 bolt pattern with Ford platform

- Luxury-oriented wheel options from 18 to 22 inches

- Premium finish options for aftermarket wheels

- Specific load rating requirements for larger wheel sizes

Conclusion

The 5×142 bolt pattern is proof of automotive engineering’s evolution, offering superior structural integrity and versatility across various vehicle applications.

From Ford F-150s to performance vehicles, this pattern has proven its worth through enhanced load distribution, improved brake clearance, and compatibility with numerous aftermarket options.

When considering wheel modifications or replacements, it’s crucial to approach the decision with careful consideration of your vehicle’s specific needs.

If upgrading for performance, style, or practical purposes, take time to verify specifications, consult professionals when needed, and prioritize proper installation procedures.

By understanding the difficulties of the 5×142 bolt pattern and following the recommended guidelines, you’ll ensure both durable performance and safety for your vehicle investment.