Mercedes-Benz, synonymous with luxury and performance, has a rich history spanning over a century.

Car enthusiasts and mechanics alike know that even the smallest details, like bolt patterns, play a crucial role in a vehicle’s design and functionality.

Over the years, these patterns have changed, reflecting the brand’s commitment to progress and precision.

This article will take you on a journey through the evolution of Mercedes-Benz bolt patterns.

We’ll explore how these seemingly minor components have adapted to changing vehicle designs and technologies.

From classic models to modern marvels, you’ll gain insights into the importance of bolt patterns and how they’ve contributed to Mercedes-Benz’s enduring legacy.

The Evolution of Mercedes-Benz Bolt Patterns

Mercedes-Benz, a pioneer in automotive engineering, has seen its bolt patterns evolve alongside its vehicles.

These seemingly small components play a crucial role in every car’s performance, safety, and aesthetics.

Let’s explore how Mercedes-Benz bolt patterns have changed over the decades.

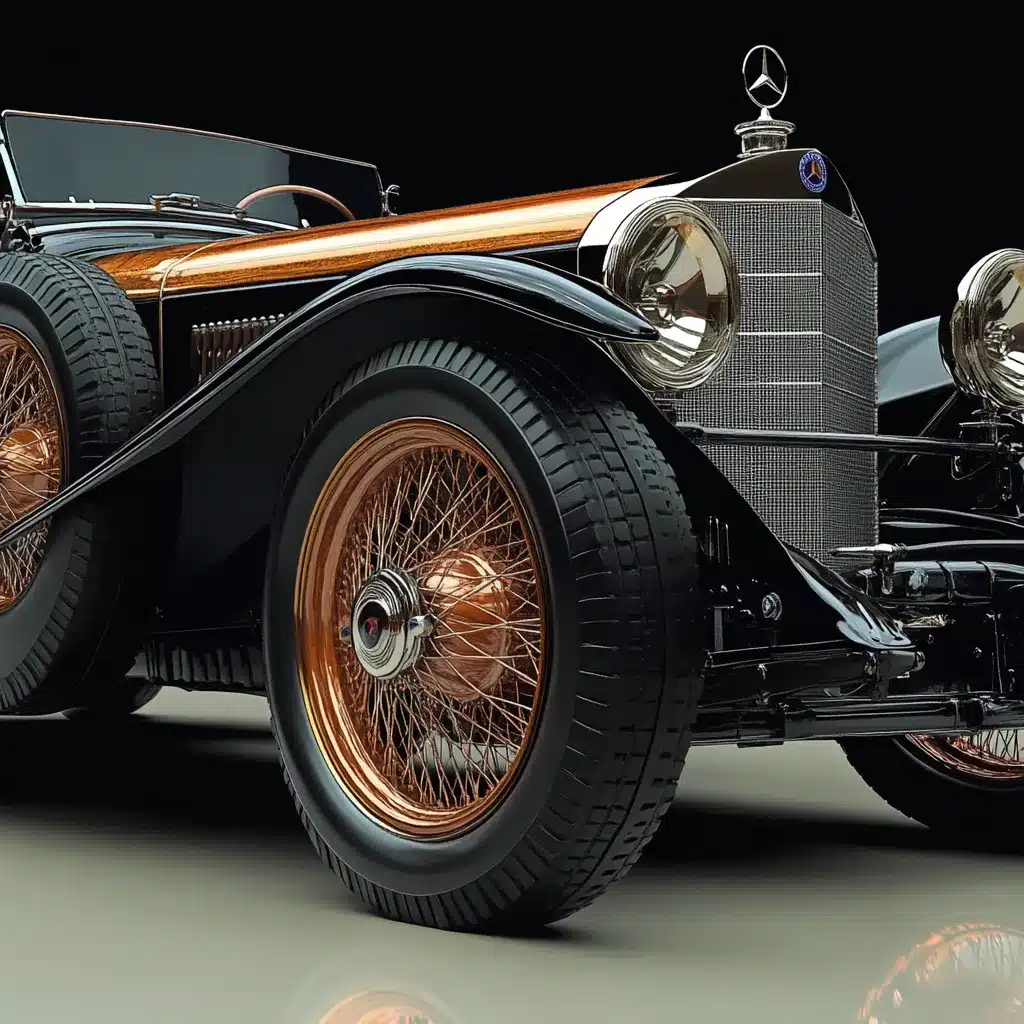

Early Beginnings (1920s-1950s)

In the early days of Mercedes-Benz, bolt patterns were as varied as the models.

The automotive industry was still finding its footing, and standardization was a distant concept.

During this period, Mercedes-Benz experimented with different bolt patterns to suit the needs of their diverse vehicle lineup.

Many early Mercedes-Benz models used unique bolt patterns tailored to the specific requirements of each vehicle.

This approach allowed for flexibility in design but also presented challenges for wheel compatibility across different models.

The rationale behind these early choices was rooted in the technological limitations of the time.

Engineers focused on creating bolt patterns that could withstand the era’s rough roads and heavy loads, prioritizing durability and safety over uniformity.

As the 1950s approached, Mercedes-Benz began moving towards more consistent bolt patterns.

This shift marked the beginning of a new era in wheel design for the brand, setting the stage for the standardization that would follow in later decades.

The transition from diverse bolt patterns to more standardized ones wasn’t just a technical change – it reflected Mercedes-Benz’s growing understanding of mass production and the benefits of interchangeable parts.

This shift would prove crucial in the decades to come.

Mid-Century Developments (1960s-1980s)

The 1960s marked a turning point for Mercedes-Benz bolt patterns.

The company began standardizing its approach during this period, adopting the 5×112 pattern for most of its passenger vehicles.

Several factors drove this move towards uniformity:

- Manufacturing efficiency: Standardization allowed for streamlined production processes.

- Improved wheel interchangeability: Owners could find compatible wheels for their vehicles more easily.

- Technological advancements: New materials and engineering techniques made it possible to create a single pattern suitable for a wide range of vehicles.

However, not all Mercedes-Benz models adopted the 5×112 pattern.

Some high-performance and specialized vehicles, particularly those developed with AMG, used a 5×130 bolt pattern.

This larger pattern provided additional strength and stability for vehicles with higher power outputs and performance requirements.

The influence of motorsports played a significant role in bolt pattern development during this era.

Mercedes-Benz’s involvement in racing pushed the limits of wheel technology, leading to innovations that eventually made their way into consumer vehicles.

Modern Era (1990s-Present)

By the 1990s, Mercedes-Benz had fully embraced the 5×112 bolt pattern as its standard for most passenger vehicles.

This consistency across the product line offered several benefits:

- Simplified inventory management for dealers and service centers

- Greater aftermarket wheel options for consumers

- Reduced manufacturing complexity

Despite the dominance of the 5×112 pattern, Mercedes-Benz has continued to use the 5×130 pattern for specific models, particularly in its SUV and high-performance AMG lines.

This dual-pattern approach allows the company to cater to diverse vehicle needs while maintaining high standardization.

Even as Mercedes-Benz has ventured into electric vehicle production in recent years, the company has largely stuck with these established bolt patterns.

This consistency demonstrates the enduring practicality of these designs, even as automotive technology continues to advance.

Factors Driving Changes in Bolt Patterns

The evolution of Mercedes-Benz bolt patterns didn’t happen in isolation.

Several key factors have influenced their development, reflecting broader trends in automotive engineering and consumer preferences.

1. Technological Advancements

Technological progress has been a major driver in the refinement of bolt patterns.

As manufacturing capabilities improved, so did the precision and consistency of wheel mounting systems.

Introducing stronger, lighter alloys allowed for more durable and precise bolt patterns.

This technological leap made the widespread adoption of the 5×112 pattern possible, as it could now meet the demanding requirements of various vehicle types.

Computer-aided design (CAD) and advanced engineering techniques have also played a crucial role.

These tools have allowed Mercedes-Benz engineers to optimize bolt patterns for specific vehicle needs while maintaining standardization across the lineup.

In recent years, the rise of electric vehicles (EVs) has brought new challenges and opportunities in bolt pattern design.

EVs’ unique weight distribution and performance characteristics may influence future bolt pattern developments.

2. Safety and Performance Considerations

Safety has always been a top priority for Mercedes-Benz, and this focus extends to bolt patterns.

Global safety regulations have pushed for more reliable and secure wheel mounting systems, favoring standardized patterns like the 5×112.

Performance demands have also shaped bolt pattern choices.

The 5×130 pattern was used in AMG models and larger SUVs due to its high-speed stability and optimal load distribution requirements.

This pattern offers additional strength and stability for vehicles with higher power outputs and performance needs.

Mercedes-Benz has skillfully balanced these considerations by adopting the 5×112 pattern for most of its lineup, providing versatility and compatibility while reserving the 5×130 pattern for specialized high-performance models.

3. Market and Consumer Demands

Consumer preferences and market trends have significantly influenced bolt pattern choices.

The growing demand for vehicle customization has made aftermarket wheel compatibility a key consideration, favoring the widespread use of the 5×112 pattern.

Global market variations have also played a role. Different regions may have specific preferences or requirements, which Mercedes-Benz has had to consider in its bolt pattern strategies.

Looking ahead, the growing electric vehicle market and increasing focus on sustainability may drive innovations in bolt pattern design.

As vehicle architectures change to accommodate new powertrains and materials, bolt patterns may evolve to meet these new challenges.

By carefully considering these factors, Mercedes-Benz has created a bolt pattern strategy that balances standardization with specialization, meeting the needs of both the company and its diverse customer base.

Case Studies: Iconic Mercedes-Benz Models and Their Bolt Patterns

Let’s examine how bolt patterns have been implemented in three iconic Mercedes-Benz model lines, showcasing the brand’s approach to this crucial design element.

1. The C-Class and Its Consistent Bolt Pattern

The C-Class exemplifies Mercedes-Benz’s commitment to bolt pattern standardization.

Since its 1993 debut, this model has exclusively used the 5×112 pattern. This consistency has had several impacts:

- Wheel interchangeability across C-Class generations

- Broad compatibility with aftermarket wheels

- Simplified logistics for dealers and service centers

The C-Class’s adherence to 5×112 demonstrates how a well-chosen bolt pattern can remain suitable despite significant changes in vehicle design and technology.

2. The Evolution of Bolt Patterns in the S-Class

The S-Class’s bolt pattern history reflects broader changes in Mercedes-Benz’s approach:

- Early models: Varied bolt patterns, mirroring the lack of industry standardization

- Mid-20th century: Transition to more uniform patterns

- Modern era: Adoption of 5×112 as the standard

Despite being a flagship model with unique requirements, the S-Class’s move to 5×112 shows how this pattern can meet the needs of even the most advanced vehicles in the lineup.

3. G-Class: A Legacy of Strength and Stability

The G-Class stands out with its consistent use of the 5×130 bolt pattern since 1979. This choice highlights several key points:

- Specialized needs: The larger pattern caters to the G-Class’s off-road and high-performance requirements

- Long-term commitment: Mercedes-Benz has maintained this pattern for over four decades, showing its effectiveness for this model

- Differentiation: The unique bolt pattern sets the G-Class apart, reflecting its special status in the Mercedes-Benz lineup

The G-Class demonstrates Mercedes-Benz’s willingness to use a non-standard bolt pattern when a vehicle’s specific needs warrant it.

The Future of Mercedes-Benz Bolt Patterns

As Mercedes-Benz looks to the future, bolt patterns may see subtle yet significant changes to meet new challenges in automotive design.

1. Innovations on the Horizon

- Smart wheel technology: Future Mercedes-Benz models might incorporate sensors directly into the wheel hubs, potentially requiring modifications to bolt patterns to accommodate these new systems.

- Lightweight materials: The push for increased efficiency could lead to developing of new, ultra-lightweight wheels and corresponding bolt patterns designed to maintain strength while reducing overall mass.

- Modular vehicle platforms: As Mercedes-Benz moves towards more flexible, modular vehicle architectures, we might see the emergence of adaptable bolt patterns that can be easily modified to suit different vehicle types on the same platform.

3. Balancing Tradition and Innovation

- Backward compatibility: Any new bolt pattern innovations will likely be designed with some backward compatibility, ensuring that older Mercedes-Benz models can still be serviced easily.

- Regional customization: Future bolt patterns might be tailored to meet specific regional requirements or preferences while still maintaining a global standard.

- Sustainable manufacturing: The production process for bolt patterns may evolve to align with Mercedes-Benz’s sustainability goals, potentially influencing their design and materials.

As Mercedes-Benz continues to lead in automotive innovation, its approach to bolt patterns will undoubtedly reflect its commitment to blending cutting-edge technology with time-tested engineering principles.

Final Thoughts

We’ve taken a fascinating trip through time, exploring how Mercedes-Benz bolt patterns have changed.

These small but crucial components tell a big story about automotive progress, from the varied designs of early models to the standardized patterns we see today.

As we look to the future, Mercedes-Benz will clearly continue to innovate, potentially reshaping bolt patterns to meet new challenges in car design.

But one thing’s for sure – whether it’s the tried-and-true 5×112 or something entirely new, Mercedes-Benz will approach bolt patterns with the same commitment to quality and performance that has made it a leader in the automotive world.

So, the next time you see a Mercedes-Benz on the road, remember – there’s a lot more to those wheels than meets the eye!