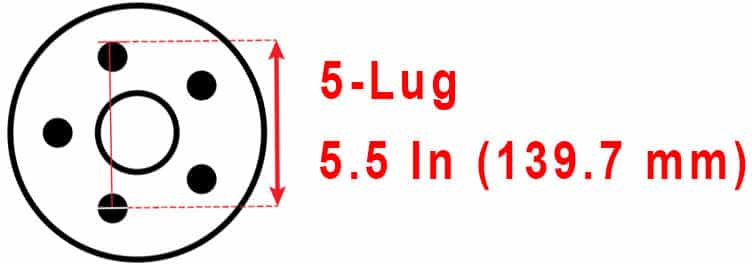

When choosing wheels for your vehicle, understanding the bolt pattern is key for a proper fit.

The 5×5.5 bolt pattern shows up often in trucks and SUVs, telling us the wheel has 5 lug holes set in a circle with a 5.5-inch diameter. Some places call this the 5×139.7mm pattern, using metric measurements.

This pattern shows up in many popular vehicles, such as Ford, Dodge, and Jeep, making it a common sight in auto shops.

It’s not just about numbers – this pattern helps your wheels stay firmly attached and handle the weight of larger vehicles.

Before you pick new wheels, knowing your bolt pattern saves time and prevents costly mistakes.

Let’s break down everything about the 5×5.5 pattern in simple terms.

Understanding 5×5.5 Bolt Pattern & Its Measurements

The 5×5.5 bolt pattern uses two key numbers that tell you everything about the wheel’s fit:

First Number (5) tells you the count of lug holes on your wheel. Having five points of contact helps spread the vehicle’s weight better than four-lug designs.

The second Number (5.5) measures the circle made by the center of the lug holes, also called the bolt circle diameter.

Picture drawing a circle through the middle of all lug holes – that circle would be 5.5 inches across.

For Global Markets:

- US and Canada: 5×5.5 inches

- Europe and Asia: 5×139.7 millimeters (same size, different unit)

A Quick Tip For Measuring: On five-lug wheels measure from the center of any lug hole to the outside edge of the hole across from it. This gives you the bolt circle diameter.

This pattern is built for strength and is often found on heavier vehicles like trucks and SUVs.

The spacing between lugs creates a solid foundation that handles both weight and road stress well.

Factors to Consider When Selecting Wheels with a 5×5.5 Bolt Pattern

| Category | Key Factors | Details |

|---|---|---|

| Vehicle Compatibility | Owner’s Manual | Check the manual for recommendations. |

| Model Year | Match the exact model year of your vehicle. | |

| Manufacturer Specs | Verify compatibility with manufacturer-recommended specifications. | |

| Factory Wheel Options | Ensure compatibility with OEM wheels. | |

| Load Ratings | Confirm load ratings match the vehicle’s requirements. | |

| Wheel Specifications | Hub Center Bore | Ensure proper alignment with your vehicle’s hub. |

| Offset | Check how far the wheel sits inward or outward. | |

| Width | Verify wheel width matches tire specifications. | |

| Rim Diameter | Confirm the correct rim diameter. | |

| Load Rating | Ensure the wheel’s load capacity supports the vehicle. | |

| Weight | Verify total wheel weight for performance considerations. | |

| Tire Considerations | Tire Size | Match tire size to the new wheels and vehicle specs. |

| Load Rating | Ensure the tire load rating meets vehicle needs. | |

| Speed Rating | Confirm the speed rating is adequate. | |

| Tire Width | Verify compatibility with wheel width. | |

| Seasonal Needs | Select tires based on seasonal requirements (e.g., winter, summer). | |

| Installation Requirements | Lug Nuts/Bolts | Use proper lug nuts or bolts for your setup. |

| Thread Pitch | Ensure compatibility with vehicle threads. | |

| Spacers | Check if wheel spacers are necessary. | |

| Hub-Centric Rings | Determine if hub-centric rings are required for alignment. | |

| Torque Specifications | Tighten to the manufacturer-recommended torque. | |

| Performance Impact | Weight | Consider total wheel weight’s effect on handling. |

| Wider Wheels | It may impact steering and stability. | |

| Larger Diameters | It can alter speedometer accuracy. | |

| Heavier Wheels | Increase braking distance. | |

| Offset | Excessive offset may cause suspension wear. | |

| Safety Aspects | Certification | Look for quality certification marks. |

| Materials | Ensure high-quality construction materials. | |

| Load Capacity | Confirm maximum load capacity. | |

| Speed Rating | Verify speed rating certification. | |

| Manufacturing Date | Ensure the wheels and tires are not outdated. | |

| Cost Factors | Purchase Price | Include initial cost considerations. |

| Installation Costs | Account for installation expenses. | |

| Extra Parts | Factor in additional parts like spacers or rings. | |

| Maintenance | Include long-term upkeep costs. | |

| Warranty | Check for coverage and terms. | |

| Additional Checks | Brake Caliper Clearance | Verify sufficient space for brake calipers. |

| Suspension Clearance | Ensure suspension components are not obstructed. | |

| Fender Clearance | Check clearance within the fenders. | |

| Steering Lock Clearance | Ensure clearance during full steering lock. | |

| Spare Tire Fit | Confirm compatibility with spare tire storage. |

Remember: Always verify measurements twice and consult professionals when unsure. The right fit means better safety and performance.

How to Install Wheels with a 5×5.5 Bolt Pattern

Before You Start

- Park on level ground

- Engage parking brake

- Gather all tools: jack, jack stands, torque wrench, lug wrench

- Check wheel specifications match your vehicle

- Place wheel chocks on the opposite end

Step-by-Step Installation

1. Preparation

- Loosen lug nuts while the wheel is on the ground

- Place the jack under the recommended lifting point

- Raise the vehicle and secure it with jack stands

- Remove old wheel

2. Initial Installation

- Clean the hub surface thoroughly

- Remove old brake dust and rust

- Check hub center bore alignment

- Position the new wheel on the hub

- Hand-thread lug nuts

3. Proper Tightening Sequence

- Start with star pattern tightening

- First round: hand tight only

- Lower the vehicle until the tires touch the ground

- Complete final torque in a star pattern

- Follow the vehicle’s torque specifications

4. Final Checks

- Verify that the wheel sits flush against the hub

- Check for proper rotation

- Test wheel for wobble

- Listen for unusual sounds

- Check tire pressure

Certain Safety Tips to Follow

- Never work under a vehicle without jack stands

- Don’t use impact tools for final tightening

- Recheck torque after 50-100 miles

- Keep lug nuts clean and dry

- Check wheel balance

Common Mistakes to Avoid During Installation

1. Improper Torque Application

- Skipping torque sequence pattern

- Not using a calibrated torque wrench

- Over-tightening lug nuts

- Using power tools for final tightening

- Missing the 50-mile retorque check

2. Surface Preparation Errors

- Leaving rust on the hub surface

- Not cleaning mating surfaces

- Installing with dirt on threads

- Failing to check for damaged studs

- Skipping thread inspection

3. Mounting Mistakes

- Not centering the wheel properly

- Missing hub rings when needed

- Using the wrong lug nut style

- Installing wheels backward

- Forgetting wheel spacer alignment

4. Safety Oversights

- Working without jack stands

- Not checking tire pressure

- Skipping wheel balance

- Failing to test fit clearance

- Missing loose component checks

5. Equipment Issues

- Using worn-out tools

- Picking wrong-sized sockets

- Mixing lug nut types

- Not replacing damaged studs

- Using incorrect jack points

6. Measurement Mistakes

- Not double-checking bolt pattern

- Ignoring offset specifications

- Missing hub bore measurements

- Skipping clearance checks

- Wrong torque specifications

Applications of the 5×5.5 Bolt Pattern in Different Vehicles

Modern Truck Applications

- Light-duty pickups (1500 series)

- Mid-size SUVs

- Full-size family SUVs

- Commercial vans

- Work trucks

Common Vehicle Brands

American Makers

- Ford F-150 (1987-1996)

- Dodge Ram 1500 (1994-2010)

- Jeep CJ Series

- Chevrolet Tracker

Asian Manufacturers

- Toyota Blizzard

- Suzuki Jimny

- Daihatsu Feroza

- Kia Sportage (older models)

Electric Vehicle Integration

- Rivian R1T (2021-2024)

- Rivian R1S (2022-2024)

Historical Usage

- First appeared in the 1940s, Jeeps

- Became standard in many 4x4s

- Still used in modern vehicles

- Proven track record in tough conditions

Benefits of The 5×5.5 Bolt Pattern

- There are more wheel options in stores because it’s a common pattern many makers use.

- Lower costs since manufacturers produce these wheels in high numbers for many vehicle models.

- Simple wheel swapping between cars with the same bolt pattern makes it useful for vehicle owners.

- Strong weight distribution across five points, adding to the safety of the wheel attachment.

- Wide parts availability at local stores and online shops makes finding replacements quick.

- Easy fitting process due to the standard spacing between lug holes.

- Long-term reliability since the pattern has proven itself over many years of use.

Why Manufacturers Choose This Pattern

- Handles heavy loads well

- Good for off-road use

- Proven reliability record

- Works with various wheel sizes

- It fits many brake systems

List of Vehicles Using 5×5.5 Bolt Pattern

| Vehicle Make | Vehicle Models | Years of Compatibility |

|---|---|---|

| Mahindra | XUV700 | 2021 – 2025 |

| Maruti | Jimny | 2018 – 2025 |

| RAM | 1500 Classic | 2019 – 2023 |

| Rivian | R1S, R1T | 2021 – 2024 |

| UAZ | Hunter, Patriot, Pickup | 2003 – 2024 |

| Suzuki | Jimny | 1987 – 2023 |

| Kia | K2500, K2700 | 2004 – 2024 |

| Ford | F-150 (2WD models) | 1987 – 1996 |

| Chevrolet/GMC | C-1500 Pickup (2WD models), Tahoe, Yukon (2WD models) | 1988 – 1998, 1992 – 1999 |

| Jeep | CJ series | 1945 – 1986 |

Conclusion

Getting your wheel installation right isn’t just about looks – it’s about safety and performance.

The 5×5.5 bolt pattern might seem like a small detail, but it plays a big role in how your vehicle handles the road.

Check your measurements twice, and don’t rush the installation steps. Keep your manual handy, follow the torque specs, and remember to check those lug nuts after your first drive.

If you’re unsure about any step, it’s worth asking a professional.

Your wheels are where the rubber meets the road – make sure they’re installed correctly.

Stay safe and happy driving!