Understanding wheel bolt patterns is crucial for vehicle maintenance and upgrades, and the 6×135 pattern represents a specific configuration that’s particularly important for Ford and Lincoln vehicle owners.

This pattern, featuring six lug holes arranged in a 135-millimeter diameter circle (or 5.3 inches), has become a standard specification for many popular trucks and SUVs.

If you’re replacing worn wheels, upgrading to aftermarket options, or customizing your vehicle’s appearance, knowing the intricacies of the 6×135 bolt pattern is essential for ensuring proper fitment and maintaining safety.

A mismatched bolt pattern can lead to serious safety issues and costly repairs, making it crucial to understand this specification before making any wheel-related modifications to your vehicle.

Understanding the 6×135 Bolt Pattern

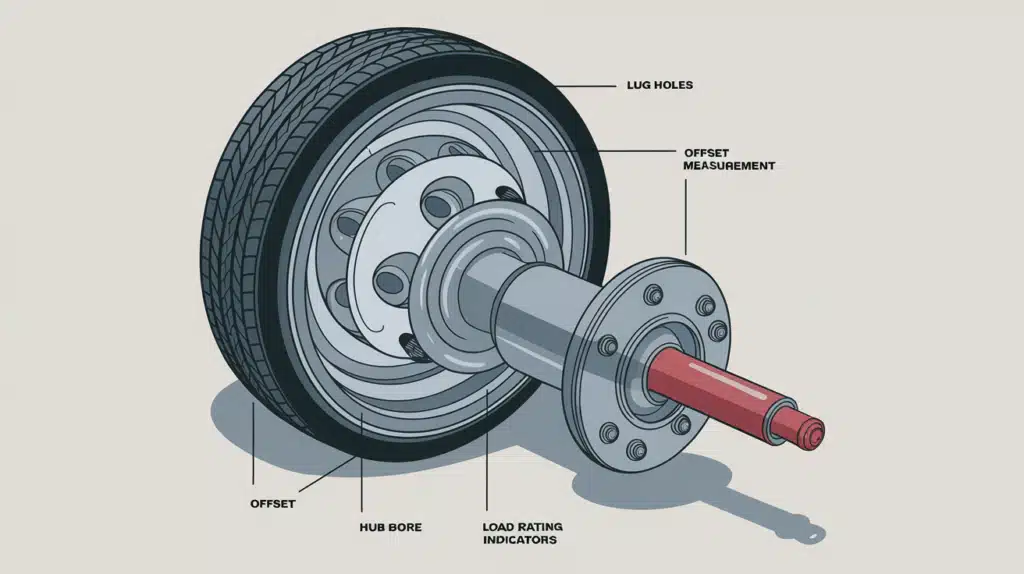

The 6×135 bolt pattern is a specific wheel configuration characterized by six lug holes arranged in a circular pattern with a diameter of 135 millimeters (or 5.3 inches).

This measurement is taken between the centers of opposite bolt holes since the six-lug design has an even number of studs.

The first number (6) indicates the number of lugs, while 135 represents the pitch circle diameter in millimeters.

This pattern requires precise measurement to ensure proper wheel fitment, as even small variations can affect vehicle safety and performance.

It’s commonly found on Ford trucks and SUVs, making it an important specification for wheel compatibility.

A Few Renowned Vehicles with 6×135 Bolt Patterns

The 6×135 bolt pattern has become a signature configuration in Ford Motor Company’s lineup, particularly in trucks and SUVs.

This standardization allows for greater wheel interchangeability within their vehicle family, though proper attention must still be paid to other specifications like hub bore and offset.

Here are the top five vehicles that prominently feature the 6×135 bolt pattern, each bringing its unique requirements and characteristics to this wheel configuration.

1. Ford F-150 (2004-2023)

- Standard 6×135 bolt pattern across all trims

- Compatible with wheel sizes from 17 to 22 inches

- Commonly used in both street and off-road configurations

- Available in both 2WD and 4WD variants

2. Lincoln Navigator (2003-2023)

- Luxury SUV sharing F-150’s platform.

- Factory-equipped with 6×135 bolt pattern

- Typically fitted with 20-22 inch wheels

- Designed for high-end wheel options and luxury aesthetics

3. Ford Expedition (2003-2023)

- Full-size SUV platform

- Maintains consistent 6×135 pattern

- Accommodates wheels from 17-22 inches

- Perfect for both stock and aftermarket applications

4. Ford Bronco (2022-2023)

- The latest addition to Ford’s 6×135 family

- Optimized for off-road performance

- Compatible with various wheel sizes

- Designed for rugged terrain capabilities

5. Ford F-150 Lightning (2022-2023)

- All-electric truck platform

- Retains traditional F-150’s 6×135 pattern

- Engineered for heavier vehicle weight

- Supports specialized EV-optimized wheel options

Factors to Consider For A 6×135 Bolt Pattern

When selecting 6×135 wheels, several critical factors need careful consideration to ensure maximum performance and safety:

- The material choice affects durability and weight – steel offers high strength at a higher weight, while aluminum alloys provide lighter options at a higher cost

- Load rating must match vehicle specifications, which is particularly important for trucks and SUVs carrying heavy loads

- Hub bore size typically ranges from 87.1mm to 93.1mm – must precisely match vehicle hub for proper fitment

- Wheel offset impacts clearance with suspension components and affects handling characteristics

- Hub-centric versus lug-centric design considerations affect wheel centering and load distribution.

Using Adapters For the 6×135 Bolt Pattern

Are you thinking about using adapters for your 6×135 wheels? Let’s talk about what you need to know. While these wheels are made mainly for Ford and Lincoln vehicles, adapters can also help them fit other cars.

But before you get excited about this option, there are some important things to consider.

When you use adapters, you’ll need to be extra careful about their installation. It’s best to have a professional do this job to ensure everything is tight and lined up right.

While adapters can be a good fix, they add some extra stress to your wheel bearings and might change how your car handles. Also, you’ll need to check them regularly to ensure they stay tight.

If you decide to use adapters, buy good ones from trusted brands. Think of adapters like shoes that don’t quite fit right – they might work for a while, but they’re not always the best long-term solution.

Still, if you take care of them properly, they can be a helpful way to use the wheels you want on your vehicle.

History of 6×135 Bolt Pattern

The 6×135 bolt pattern emerged as a significant wheel specification when Ford introduced it on their F-150 lineup in 2004, marking a shift from previous patterns.

This six-lug design was specifically engineered for Ford’s larger vehicles, becoming standard across their full-size truck and SUV platforms, including the Expedition and later the Bronco.

Lincoln, Ford’s luxury division, also adopted this pattern for their Navigator and Mark LT models from 2003 onwards.

The pattern has remained consistent in Ford’s heavy-duty vehicle lineup for nearly two decades, demonstrating its durability and success in supporting larger vehicles’ load-bearing requirements.

Installing 6×135 Wheels

Installing 6×135 wheels requires careful attention to detail and proper tools for safe mounting. Start by ensuring you have a torque wrench, jack, jack stands, wheel chocks, and appropriate sockets.

Begin by parking on a level surface and engaging the parking brake. After lifting the vehicle and securing it with jack stands, remove the old wheels while noting the proper torque specifications.

Clean the hub surface thoroughly and check for any damage. When mounting the new 6×135 wheels, insert all six lug nuts and hand-tighten them in a star pattern before using the torque wrench to achieve proper specifications.

This cross-pattern tightening is crucial for even pressure distribution. After installation, recheck the torque after driving 50-100 miles to ensure wheel security.

Mistakes to Avoid During Installation

Drawing from the source material and common wheel installation practices, here’s a focused look at crucial installation mistakes to avoid:

When installing 6×135 wheels, never skip torque specifications or rely on impact guns alone for final tightening, as this can lead to uneven pressure distribution across the six lugs.

A common error is failing to clean the hub surface and mating faces, which can cause wheel wobble and premature wear.

Avoid using incorrect lug nuts or mixing hardware types – the hub bore size, typically ranging from 87.1mm to 93.1mm for these wheels, must match precisely without forced fitting.

Never skip the critical step of rechecking torque after the initial drive period, as wheels can lose tension during the break-in period.

Additionally, using thread-locking compounds without manufacturer approval can interfere with proper torque readings and future maintenance.

Applications of 6×135 Bolt Pattern

The 6×135 bolt pattern is predominantly used in Ford and Lincoln vehicles, particularly in heavy-duty applications.

This pattern is most commonly found on Ford F-150 trucks (2004-2023), Ford Expedition SUVs (2003-2023), and Lincoln Navigator models (2003-2023).

The pattern has also been adopted for newer vehicles like the Ford Bronco (2022-2023) and F-150 Lightning electric truck.

OEM and aftermarket manufacturers offer wheels in this pattern, ranging from standard steel wheels for utility purposes to specialized alloy variants for enhanced performance and aesthetics.

This specification is particularly popular in the off-road and heavy-duty vehicle segments.

Benefits of the 6×135 Bolt Pattern

The 6×135 bolt pattern offers significant advantages for heavy-duty vehicles through its durable design and engineering.

The 6-lug configuration provides superior load distribution to patterns with fewer lugs, making it ideal for trucks and SUVs carrying heavy loads or towing.

This pattern delivers enhanced stability during demanding conditions, which is particularly important for vehicles like the Ford F-150 and Expedition.

Key advantages include:

- Improved weight distribution across six points of contact, reducing stress on individual lugs

- Enhanced durability for off-road applications and rough terrain

- Better brake heat dissipation due to the wheel’s secure mounting

- Increased stability during heavy payload transportation

- Superior torque handling capability, essential for towing operations

The pattern’s 135mm diameter also provides sufficient clearance for larger brake components, making it particularly well-suited for vehicles that require heavy braking systems.

This combination of features explains why manufacturers like Ford have made it their standard choice for heavy-duty applications.

The Bottom Line

The 6×135 bolt pattern represents more than just a technical specification – it’s crucial in ensuring your vehicle’s safety, performance, and reliability.

If you own a Ford F-150, Lincoln Navigator, or any other compatible vehicle, understanding this pattern is essential for making informed decisions about wheel upgrades and replacements.

The correct fitment not only enhances your vehicle’s performance but also ensures your and your passengers’ safety.

As you consider wheel modifications or replacements, take the time to verify all specifications, including bolt pattern, hub bore size, and offset.

Making educated choices about your vehicle’s wheels isn’t just about style – it’s an investment in your safety and your vehicle’s long-term performance.