Building a deck in Illinois comes with its own set of challenges. The weather here isn’t exactly gentle on outdoor structures. If you’ve ever dealt with concrete footings, you know what I’m talking about. They crack, shift, and sometimes just don’t hold up the way you’d expect. That’s where helical piles come in, and honestly, they’re changing the game for deck foundations.

Illinois has a frost line that sits at about 42 inches deep. Traditional concrete footings need to go down pretty far to avoid frost heave. When the ground freezes and thaws repeatedly, it can push concrete footings around like they weigh nothing. Helical piles offer a smarter alternative that works with Illinois soil conditions instead of fighting against them.

What Are Helical Piles?

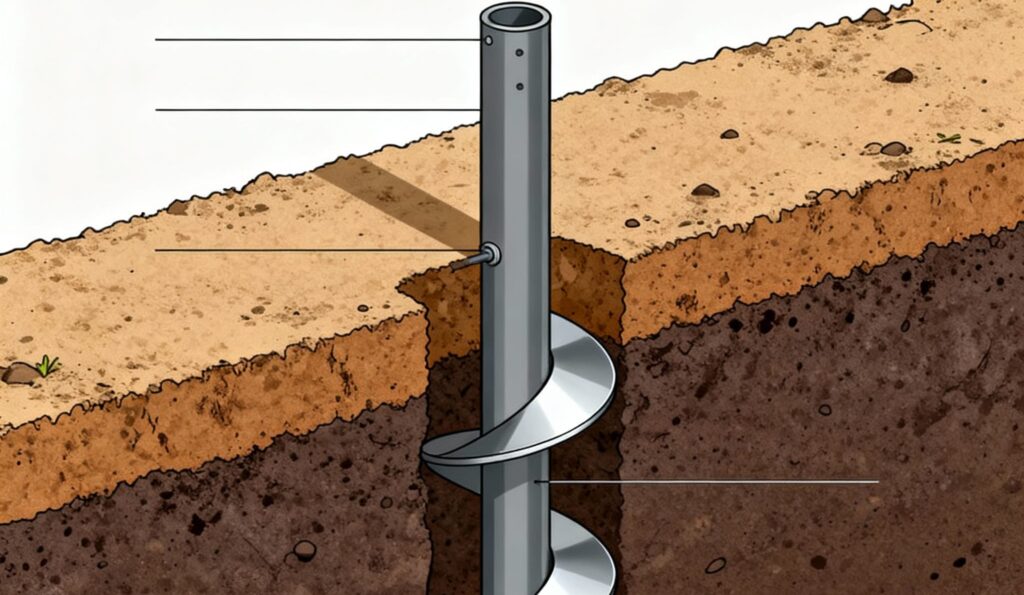

Think of helical piles like giant screws for your deck. They’re made from a steel shaft with spiral plates (called flights) welded onto it. These plates look exactly like the threads on a screw, which is why some people call them screw piles or helical piers.

A crew uses hydraulic equipment to literally screw these steel shafts into the ground until the pile reaches stable, load-bearing soil. The construction comes in different sizes:

- Solid steel bar: 1.5 to 2.5 inches in diameter (perfect for standard residential decks).

- Tubular varieties: 2.75 to 12 inches in diameter (for heavier or multi-level structures).

Those helical plates distribute the weight of your deck across a larger area of soil. Instead of relying on a single concrete base at frost line depth, the helical design grabs onto multiple soil layers as it goes down. The deeper it goes, the more stable it gets.

Why Helical Piles Excel in the Illinois Climate

Now, let’s talk about why these things are perfect for Illinois. Our state has dramatic temperature swings. Summers can hit 95 degrees, and winters can drop to minus 10 or worse. That freeze-thaw cycle is brutal on traditional foundations. Illinois soil throws serious curveballs at deck foundations:

- Freeze-thaw cycles that happen dozens of times each winter.

- Frost heave that can lift structures several inches.

- Expansive clay soils swell when wet and shrink when dry.

- High water tables in areas near rivers and lakes.

- Temperature swings of over 100 degrees between seasons.

Concrete footings face several problems here. When the ground freezes, it expands. When it thaws, it contracts. This constant movement creates frost heave, which can lift your entire deck structure. Concrete also absorbs moisture, and when that moisture freezes, it causes cracks and deterioration.

Helical piles sidestep these issues completely. Steel doesn’t expand and contract with temperature changes the way concrete does. The galvanized coating protects against corrosion, giving you 20-plus years of solid performance. Because the piles are anchored deep into stable soil layers, frost heave can’t touch them.

Another huge advantage? Immediate load capacity. With concrete, you’re waiting 7 to 28 days for it to cure. Helical piles can support the same weight as they’re installed.

Installation Advantages for Illinois Deck Projects

The installation process for helical piles is honestly impressive. What would take days with concrete footings happens in hours with helical piles. You can literally have your foundation set and start building your deck frame the same day.

Here’s what makes the installation process so much better:

- Same-day deck building is possible (no waiting for concrete to cure).

- All-weather installation capability (rain, shine, or light snow).

- Minimal excavation and soil disturbance.

- No spoils removal needed.

- Easy adjustment and leveling during installation.

- Direct torque-to-capacity relationship for quality control.

Try pouring concrete in the rain and see how that goes. You can’t. But helical piles don’t care about the weather. When you’re working with deck builders in Illinois who use helical piles, weather delays become a thing of the past.

There’s also a quality control aspect that concrete can’t match. During installation, the hydraulic equipment measures torque. That torque reading directly correlates to the load capacity of the pile. It’s real-time verification that your foundation can handle the weight.

Cost Considerations for Illinois Homeowners

Let’s talk money. Helical piles typically cost between $300 and $500 per pile for deck installations. At first glance, that might seem higher than concrete footings. But here’s where it gets interesting when you look at the full picture.

|

Cost Factor |

Helical Piles |

Concrete Footings |

|---|---|---|

|

Material & Installation |

$300-$500 per pile |

$200-$400 per footing |

|

Labor Time |

Same-day installation |

Multi-day process |

|

Excavation & Cleanup |

Minimal, no spoil removal |

Digging, dirt removal fees |

|

Weather Delays |

None |

Rain delays common |

|

Return Visits |

Not needed |

Required after curing |

|

Long-term Maintenance |

Virtually none |

Crack repairs possible |

When you factor in labor costs, eliminated return visits, and faster completion, helical piles often come out ahead. Most residential decks use between 6 and 12 piles. Several factors affect the final price:

- Number of posts your deck design requires.

- Local soil conditions and depth to stable strata.

- Load capacity requirements.

- Accessibility of your yard for installation equipment.

The long-term savings matter too. Helical piles don’t settle or shift like concrete can, which means fewer maintenance headaches. Most homeowners see ROI within the first few years from avoided repairs.

Permits and Code Compliance in Illinois

Every deck project in Illinois requires a building permit, and your foundation needs to meet specific code requirements. Helical piles meet or exceed Illinois building code standards when installed correctly.

Your permit application will need engineered drawings showing the foundation design. For helical piles, this includes soil investigation data and load calculations. Inspectors actually prefer helical piles in some ways because the load testing happens during installation.

Working with experienced deck builders in Illinois who are familiar with helical pile installations makes the permit process smoother. They know what local building departments require and can provide the necessary documentation without delays.

Conclusion

If you’re planning a deck project, foundation choice affects everything that comes after. Helical piles give you a faster timeline, better performance in Illinois weather conditions, and peace of mind that your deck will stay level and stable for decades.

The technology isn’t experimental. Helical piles have been used in commercial construction for years and are now becoming the smart choice for residential deck projects. When you’re talking to contractors about your project, ask about helical piles. Not every contractor offers them yet, but the ones who do are typically staying ahead with better building practices.

Your deck is an investment in your home and your lifestyle. Starting with a foundation that’s built to handle Illinois’ challenging climate just makes sense. Helical piles might cost slightly more upfront, but the speed, durability, and long-term performance make them worth every penny.