Wheel bearings are pivotal in ensuring your vehicle’s smooth operation and safety on the road.

Inevitably, these components wear out over time due to the constant stress and friction they endure, necessitating replacement.

This detailed blog aims to equip you with a thorough understanding of the factors influencing wheel bearing replacement costs.

I will examine crucial aspects such as the vehicle’s make and model, the type and quality of replacement bearings, labor costs, and any additional components that may require replacement.

Additionally, I will emphasize the importance of timely bearing replacement and provide insightful information to help you budget effectively.

Let’s go through this informative guide and empower you with the knowledge to navigate the dynamics of wheel bearing replacement costs confidently.

Factors Influencing the Replacement Cost

Multiple key factors play a significant role in determining the overall cost of wheel bearing replacement.

- Firstly, the make and model of your vehicle can substantially impact the cost, with luxury and high-performance vehicles often requiring specialized, more expensive bearings designed to withstand greater loads and higher speeds.

- Additionally, the specific type of wheel bearing – whether ball, roller, or tapered – can affect the replacement cost, as some varieties incorporate more advanced engineering and materials, inherently increasing their price point.

- The quality of the replacement bearings is another crucial consideration that cannot be overlooked.

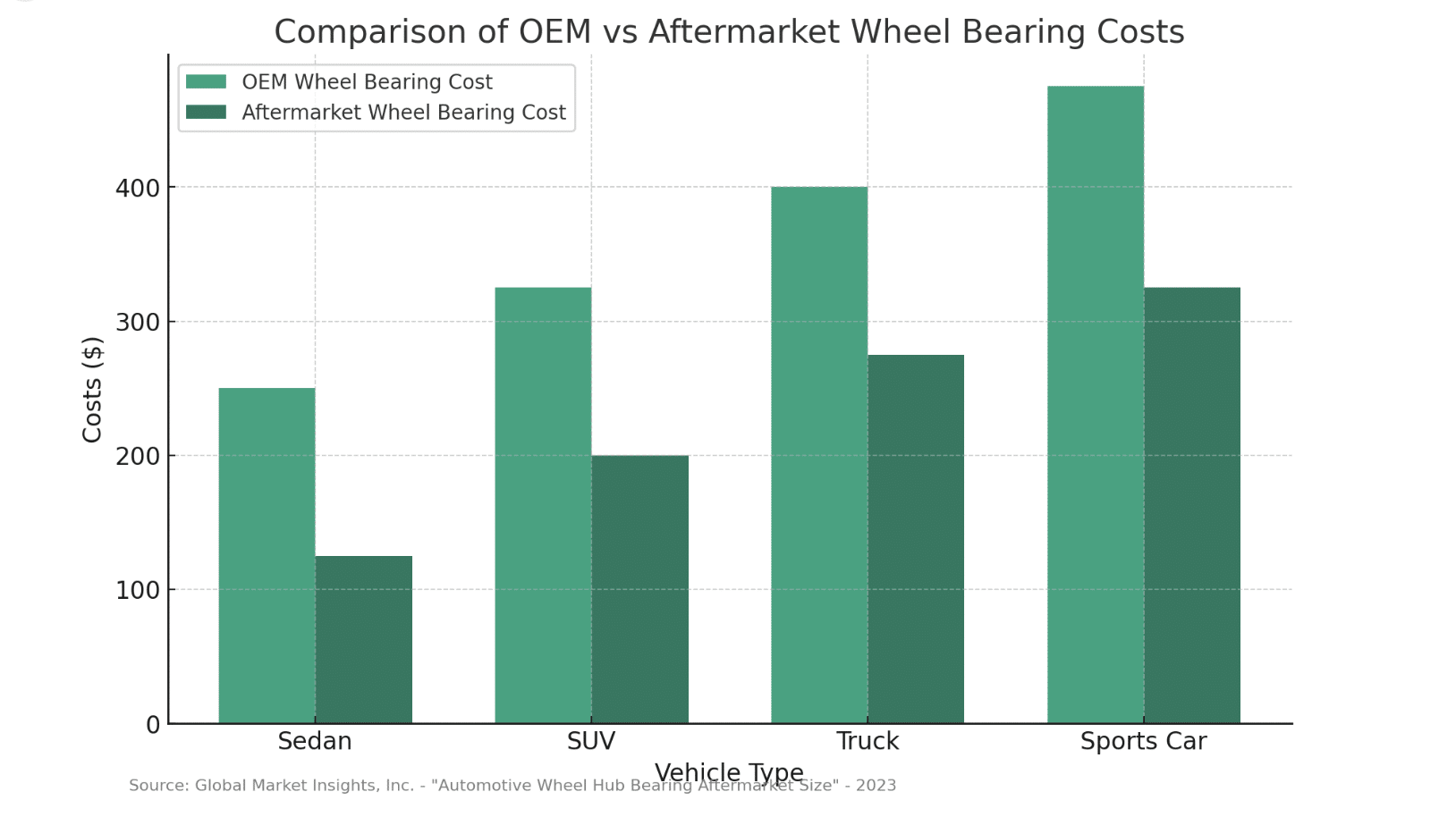

- Original Equipment Manufacturer (OEM) bearings sourced directly from the automaker tend to command a premium price, but they offer superior fitment, durability, and compatibility with your vehicle’s intricate systems.

- Conversely, aftermarket bearings are generally more affordable. Still, their quality can vary significantly between brands, with some offering comparable performance to OEM parts while others may fall short in longevity or precision.

- Labor costs are also a major factor that contributes significantly to the overall expense, influenced by the complexity of the replacement job, accessibility of the wheel bearings, and regional labor rates charged by service providers.

In some cases, additional components like wheel hubs, seals, or axle nuts may need to be replaced alongside the bearings, further increasing the overall cost.

To illustrate the potential cost variations, replacing wheel bearings on a standard sedan could cost between $100 and $300 per wheel, including parts and labor. However, for a luxury SUV equipped with premium bearings, the cost could escalate to $200 to $500 per wheel, not including potential additional component replacements that may be necessary.

Average Costs of Replacement by Vehicle Type

| Vehicle Type | Part Cost Range ($) | Labor Cost Range ($) | Total Cost Range ($) |

|---|---|---|---|

| General | 50 – 350 | 100 – 300 | 150 – 650 |

| Standard Vehicles | 100 – 300 | 100 – 300 | 200 – 600 |

| Premium or High-Performance | 200 – 500 | 100 – 300 | 300 – 800 |

| OEM Bearings | 300 – 700 | 100 – 300 | 400 – 1000 |

| Compact Car (e.g., Honda Civic) | 200 – 400 | 100 – 300 | 300 – 700 |

| Mid-size SUV (e.g., Ford Explorer) | 300 – 600 | 100 – 300 | 400 – 900 |

| Luxury Sedan (e.g., BMW 5 Series) | 400 – 800 | 100 – 300 | 500 – 1100 |

The average wheel bearing replacement cost can vary significantly based on your vehicle’s type and the specific bearings required.

- In general, parts alone can range from $50 to $350 per wheel bearing, while labor expenses can add $100 to $300 or more per wheel, depending on the service provider’s rates and the job’s complexity.

- When accounting for both parts and labor costs, standard wheel bearings commonly found in many mainstream vehicles cost between $100 and $300 per bearing.

- However, premium or high-performance wheel bearings designed for sports cars, luxury vehicles, or heavy-duty trucks can escalate costs substantially, often ranging from $200 to $500 or more per bearing installed.

- OEM bearings sourced directly from the vehicle manufacturer are typically the most expensive option, with costs ranging from $300 to $700 or higher per bearing, including labor.

- To provide a more tangible perspective, replacing the wheel bearings on a compact car like a Honda Civic could cost between $200 and $400 per wheel, including both parts and labor. For a mid-size SUV like a Ford Explorer, the costs may range from $300 to $600 per wheel.

- And for a luxury sedan like a BMW 5 Series, you could be looking at a substantial investment of $400 to $800 per wheel bearing replacement, depending on the specific model and service provider.

It’s essential to note that several additional factors can influence these costs, such as the vehicle’s make, model, age, and overall condition.

Older, high-mileage vehicles may require additional repairs or replacements during the bearing installation process, increasing expenses.

Ensure you work in a safe, level area with the vehicle properly supported on jack stands or a lift.

Gather all necessary tools and have the new wheel bearings ready and easily accessible.

For added safety, chock the wheels and apply the parking brake to prevent any unintended movement of the vehicle.

Costs can also vary based on your geographic location and the specific service provider’s labor rates. Urban areas and dealerships often command higher prices than independent mechanics in more rural regions.

Step-by-Step Replacement Process

Replacing worn wheel bearings is critical for maintaining your vehicle’s safety and performance on the road. Damaged or failing bearings can lead to many issues, including uneven tire wear, steering instability, and even the potential for complete wheel separation if left unchecked for an extended period.

Following the correct steps and utilizing the appropriate tools is imperative to ensure a proper and safe replacement:

- Remove the Wheel: Remove the wheel and access the bearing assembly by disconnecting any necessary components (brake caliper, rotor, etc.) according to the manufacturer’s instructions.

- Bearing Press: Use the bearing press (or hub puller for press-fit bearings) to carefully remove the old, worn bearing from the hub assembly without damaging any surrounding components.

- Install the New Bearing: Before installing the new bearing, thoroughly clean the hub assembly area, removing dirt, debris, or residual grease or sealant.

- Seat and Press: Properly seat and press in the new bearing using the bearing press, ensuring correct alignment and following any specific installation procedures recommended by the bearing manufacturer.

- Reassemble: Reassemble the hub assembly, brake components, and wheel using the torque wrench to torque all fasteners to the exact specifications provided by the vehicle manufacturer.

Testing and Post-Replacement Checks

- Take the vehicle for a thorough test drive, listening attentively for any abnormal noises that may indicate improper installation or remaining issues with the bearings or related components.

- Assess the ride quality and steering response, ensuring no vibrations or instability indicate misalignment or other problems.

- Check that the steering wheel is properly centered and that no noticeable alignment issues may have resulted from the bearing replacement process.

- Inspect the work area thoroughly to ensure no tools or components were inadvertently left behind, which could potentially cause safety hazards or further mechanical issues.

Proper maintenance is key to maximizing the life of your new wheel bearings and protecting your investment.

Clean the areas around the bearings regularly, protecting them from water, dirt, and debris build-up that can accelerate wear.

Additionally, avoid high-impact loads or harsh driving conditions that could subject the bearings to excessive stress and potentially damage them prematurely.

With the right care and attention, your new bearings should provide smooth, reliable performance for years, contributing to your vehicle’s overall safety and longevity.

Conclusion

Regular maintenance and professional inspections are essential for ensuring the safety and optimal performance of your vehicle’s wheel bearings over time.

By addressing bearing issues promptly and scheduling timely replacements as needed, you can avoid more costly repairs down the line and optimize the performance of these critical components that play a vital role in your vehicle’s handling and stability.

- When it comes to cost-effective wheel bearing replacement, it’s crucial to examine your options carefully and weigh the pros and cons of each choice.

- While OEM parts sourced directly from the vehicle manufacturer may carry a higher initial price tag, they often provide superior durability, fitment, and compatibility with your specific vehicle’s systems.

- However, high-quality aftermarket bearings from reputable brands can also be a viable and more affordable option, especially for budget-conscious consumers, as long as you do your due diligence and choose a trusted provider.

It’s also essential to consider the expertise and labor rates of your chosen service provider, as these can significantly impact the overall cost of the replacement process.