The custom printing industry is evolving rapidly, offering various techniques to bring designs to life on fabric. Whether you’re starting a print-on-demand business, upgrading your custom apparel setup, or exploring new printing methods, two technologies stand out: DTF (Direct-to-Film) printing and DTG (Direct-to-Garment) printing.

Both offer high-quality prints, but they work differently and suit different needs. Choosing the right one depends on your business goals, budget, and the types of products you want to print. This guide will break down how DTF and DTG printing work, their key differences, and which one is best for your business.

What is DTF Printing?

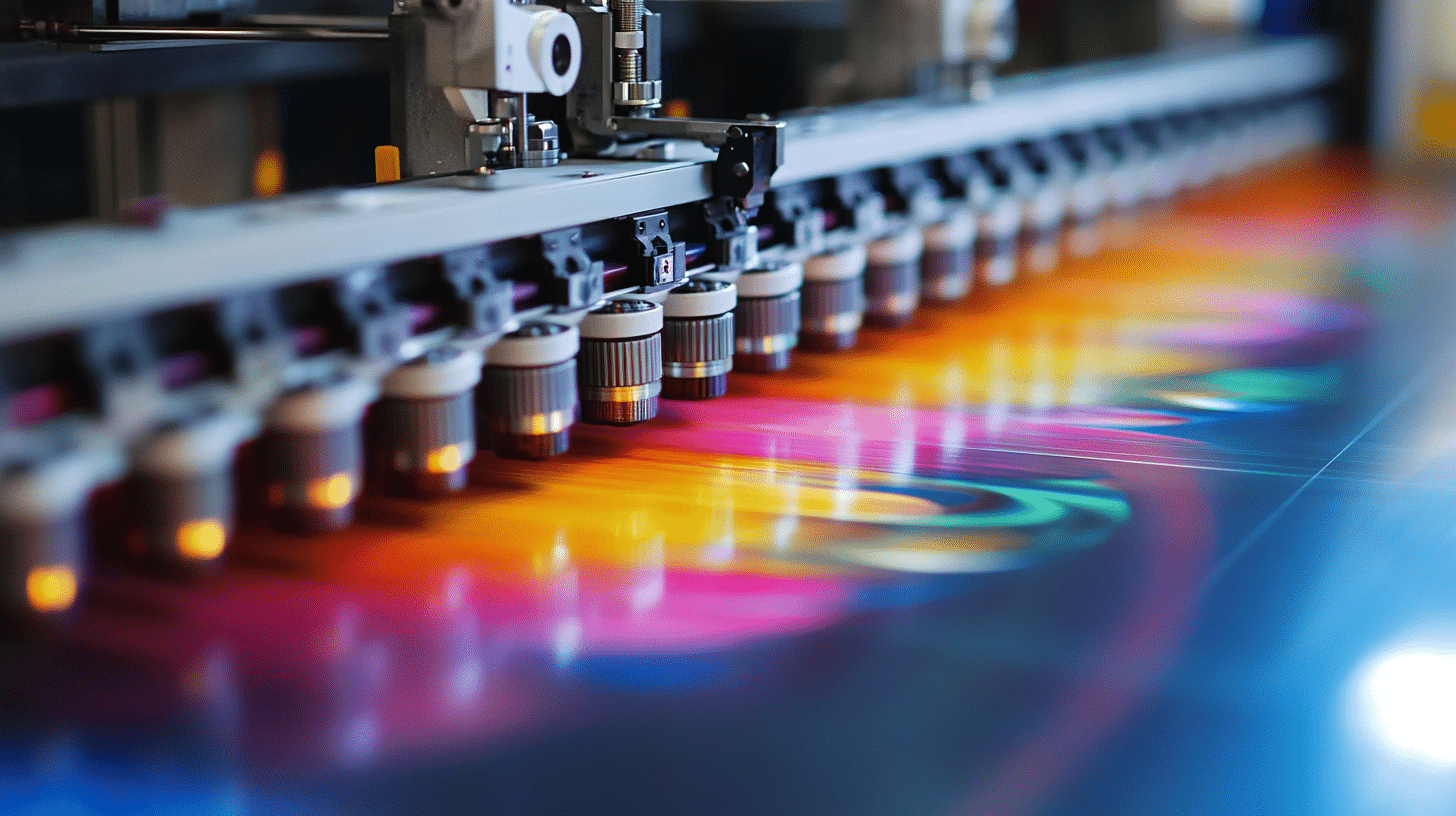

DTF printing is a relatively new technique that allows you to print designs on a special transfer film, apply an adhesive powder, and then heat-press the design onto fabric. Unlike traditional methods, DTF doesn’t require pre-treatment, making it a popular choice for businesses that need efficiency and versatility.

The process starts with printing an image onto a PET film using specialized textile ink. Once printed, a hot-melt adhesive powder is evenly spread over the design. The film is then heated to cure the adhesive before being transferred onto the fabric using a heat press. After cooling, the film is peeled away, leaving a vibrant and durable print on the material.

One of DTF’s biggest advantages is its compatibility with various fabrics. It works on cotton, polyester, blends, leather, and even nylon. Unlike DTG, which struggles with synthetic materials, DTF offers a reliable solution for businesses that need flexibility. The prints are also highly durable and resistant to washing, stretching, and fading over time.

However, DTF printing does require additional steps. The powder application and curing process add time to production. The prints also have a slightly thicker texture compared to DTG, which some customers may prefer while others might find less appealing.

What is DTG Printing?

DTG (Direct-to-Garment) printing is a digital inkjet method that applies water-based ink directly onto fabric. It’s best known for producing soft, high-quality prints with detailed gradients and textures.

The process begins with pre-treating the fabric, a crucial step that ensures the ink bonds correctly. Without this, the ink won’t adhere properly, leading to fading or dull colors. After pre-treatment, the garment is placed into a DTG printer, which applies ink directly onto the fabric in precise layers. Once printed, the garment is cured using heat to set the ink.

DTG prints feel soft because the ink soaks into the fabric rather than sitting on top. This makes it ideal for detailed, photorealistic designs, particularly on cotton-based materials. However, DTG printing struggles with synthetic fabrics like polyester, where ink absorption is a challenge.

While DTG offers excellent print quality, it does come with some drawbacks. Pre-treatment adds an extra step to production, increasing processing time. The ink is also more expensive than other printing methods, making it less cost-effective for large-scale orders. Additionally, DTG prints tend to fade faster over time, especially when washed frequently.

DTF vs. DTG Printing: Key Differences

When comparing DTF and DTG printing, several factors determine which one is better for your business.

Print quality is an important consideration. DTG prints are incredibly soft, blending seamlessly with the fabric, while DTF prints sit on top, giving them a slightly thicker texture. However, DTF prints tend to last longer, resisting cracking, peeling, and fading more effectively.

Fabric compatibility is another major difference. DTG works best on 100% cotton garments, producing vibrant and highly detailed prints. In contrast, DTF can be used on almost any material, including polyester, blends, denim, and even synthetic fabrics, making it a more versatile choice.

Cost is often a deciding factor. DTF requires consumables like transfer film and adhesive powder, but it’s more cost-efficient for bulk production. DTG, on the other hand, has higher ink costs, and the pre-treatment process increases material expenses. If you’re printing large volumes, DTF may offer better long-term savings.

Production speed also varies between the two methods. DTG is typically faster for single-item prints because the ink is applied directly onto the fabric. However, for bulk orders, DTF can be more efficient. Once the films are prepared, they can be quickly transferred onto multiple garments without repeating the printing process.

Durability is another crucial factor. DTF prints hold up well after multiple washes, maintaining their vibrancy and structure. DTG prints, while initially softer, tend to fade more quickly, particularly when used on fabrics other than cotton.

Finally, maintenance requirements differ. DTG printers require regular upkeep, including frequent cleaning to prevent ink clogs. DTF printers also need maintenance, but they don’t rely on pre-treatment liquids, reducing potential issues.

Which Printing Method is Best for Your Business?

Choosing between DTF and DTG depends on your specific business needs.

If you want to print on a wide variety of fabrics, including synthetics and blends, DTF is the better option. Its durability and versatility make it ideal for businesses that produce bulk orders or need long-lasting prints. DTF is also a great choice for companies looking to streamline production since it eliminates the need for pre-treatment.

DTG is a better fit if you primarily print on cotton and prioritize a soft-touch feel. The ink penetrates the fabric, creating a seamless design with detailed color gradients. If your business specializes in print-on-demand services, where single-item production is common, DTG might be the more efficient choice. However, keep in mind that pre-treatment and ink costs can add up over time.

Some businesses even use both methods to maximize efficiency and offer a broader range of products. For example, DTG might be the go-to choice for cotton T-shirts with highly detailed artwork, while DTF is used for polyester hoodies, tote bags, or workwear.

A major consideration when investing in DTF technology is selecting the right equipment. The Epson F2270 DTF printer is a popular choice for businesses looking for high-quality prints with reliable performance. It offers a balance of efficiency and precision, making it a solid investment for those serious about DTF printing.

Final Verdict: Which One Should You Choose?

Both DTF and DTG printing have distinct advantages. If you need versatility, durability, and the ability to print on different fabrics, DTF is the clear winner. If you focus on soft-touch prints, artistic detail, and high-end custom apparel, DTG may be the better choice.

Ultimately, the right method depends on your business model. If you’re running a print-on-demand service with small orders, DTG is an excellent option. If you’re handling bulk production or want the flexibility to print on multiple materials, DTF is the way to go.

Before making a decision, consider factors like material costs, production speed, and long-term scalability. If your business is growing, having both DTF and DTG capabilities might be the smartest move, allowing you to meet different customer demands without limitation.

Would you like to see real-world case studies comparing both methods? Let us know in the comments!