When it comes to roofing systems, most homeowners focus on the visible elements, such as shingles, tiles, or metal panels, that protect their homes from the elements.

However, beneath these outer layers lies a critical structural component that often goes unnoticed: roof decking.

This essential foundation serves as the backbone of your entire roofing system, yet many property owners remain unfamiliar with its purpose and importance.

If you’re a homeowner preparing for a roofing project or simply want to better understand your home’s construction, we will walk you through everything you need to know about roofing components.

What is Roof Decking?

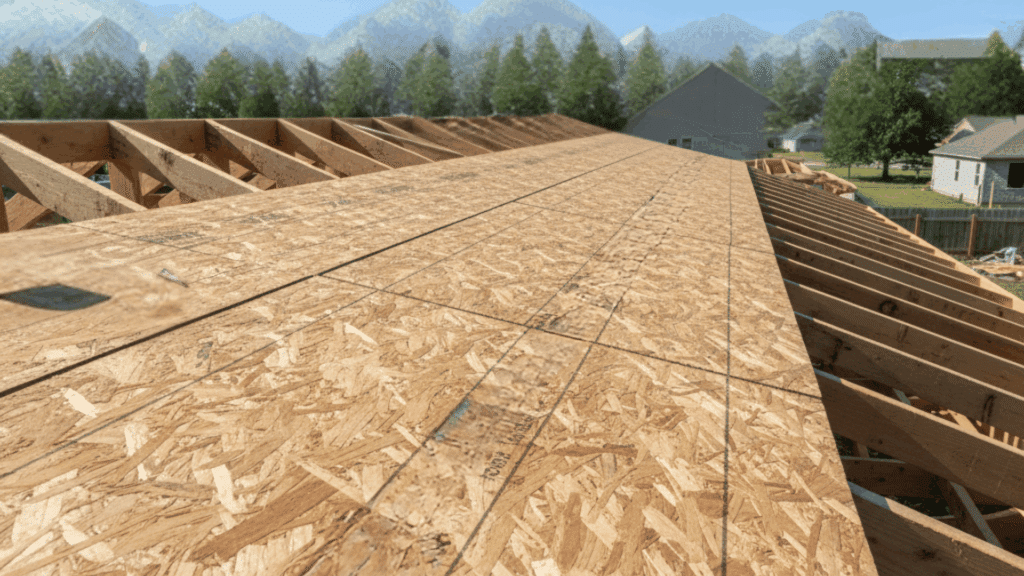

Roof decking is the structural foundation of your roof, acting as the base layer that supports all other roofing components.

Typically made from plywood, OSB, or plank boards, the decking is fastened directly to the roof’s framing to create a strong, stable surface.

Its main job is to distribute weight evenly, reinforce the roof structure, and help protect your home from weather-related damage.

A solid roof deck ensures durability, prevents sagging, and maintains the integrity of the entire roofing system. If the decking becomes weakened by moisture, rot, poor ventilation, or aging materials, it can compromise your roof’s performance.

Understanding what decking does helps homeowners make informed decisions during repairs, inspections, or full roof replacements

Types of Roof Decking Materials

Understanding the different types of roof decking materials helps you select the best foundation for your roofing system.

1. Plywood

Traditional and reliable roofing material made from thin wood veneers glued together in alternating grain patterns.

Offers excellent strength, durability, and moisture resistance, making it a preferred choice for residential applications.

Plywood roof decking typically comes in 4×8 foot sheets with thicknesses ranging from 3/8″ to 3/4″, with 1/2″ and 5/8″ being most common for residential roofing.

| Pros | Cons |

|---|---|

| Superior strength and consistent quality | Higher cost compared to alternatives |

| Better moisture resistance than OSB | Can delaminate if exposed to prolonged water |

2. OSB (Oriented Strand Board)

An engineered wood product manufactured from compressed wood strands and resin adhesive.

It is a cost-effective alternative to plywood, widely used in modern residential construction due to its affordability and adequate structural performance.

Standard panel sizes match plywood dimensions, with 7/16″ being the IRC minimum thickness for roof applications with 24″ rafter spacing .

| Pros | Cons |

|---|---|

| More economical than plywood | Swells more when exposed to moisture |

| Consistent manufacturing eliminates weak spots | Longer drying time if wet |

3. Plank Decking (Tongue-and-Groove Boards)

Solid wood boards with interlocking edges, traditionally used in older homes and exposed-beam construction.

Provides rustic aesthetic appeal while delivering structural support, often left visible from interior ceilings.

Tongue-and-groove roof decking typically uses 2×6 or 2×8 boards made from species like pine, fir, cedar, or hemlock, installed perpendicular to roof beams or purlins.

| Pros | Cons |

|---|---|

| Aesthetically pleasing for exposed applications | More expensive than sheet materials |

| Natural insulation properties | Gaps can develop as wood ages |

4. Concrete Roof Decking

Heavy-duty material consisting of precast or poured concrete slabs.

Primarily used in commercial buildings, parking structures, and multi-story constructions requiring superior fire resistance and load-bearing capacity.

Thicknesses from 4-12 inches support high-rises, where 3+ hour fire ratings often meet strict codes; less common in residential builds.

| Pros | Cons |

|---|---|

| Exceptional fire resistance and durability | Requires stronger structural support due to weight |

| Minimal maintenance requirements | Not suitable for residential applications |

5. Metal Roof Decking

Steel panels with corrugated profiles, commonly used in commercial and industrial buildings. Provides non-combustible, lightweight structural support that spans long distances between beams efficiently.

Metal roof decking utilizes galvanized or galvalume-coated steel sheets in gauges ranging from 22 to 16 (thicker numbers indicate thinner material), with profiles including Type B (wide rib), Type A (narrow rib), and Type F (intermediate rib), designed for different span capabilities.

| Pros | Cons |

|---|---|

| Lightweight yet extremely strong | Prone to rust without proper coating |

| Fire-resistant and long-lasting | Condensation issues require proper insulation |

What Causes Roof Decking Damage?

Roof decking damage is typically the result of moisture exposure, structural stress, or aging materials.

One of the most common causes is water intrusion from leaks, missing shingles, or damaged flashing, which allows moisture to seep into the wood and lead to rot.

Poor attic ventilation can also trap humid air, causing the decking to warp, soften, or grow mold over time.

Ice dams in colder climates force melting snow under shingles, accelerating moisture damage. Heavy loads from snow, debris, or foot traffic can stress the decking and weaken its strength.

In older homes, decking may deteriorate simply due to age, outdated materials, or previous improper installation.

Signs Your Roof Decking Needs Repair or Replacement

Your roof often shows early clues when its decking starts to fail. Here’s what to look for.

- Sagging or uneven rooflines, visible from the outside.

- Soft or spongy spots you can feel when walking on the roof.

- Water stains or discoloration on ceilings or attic walls.

- Visible mold, mildew, or rot in the attic or on the decking boards.

- Persistent roof leaks or moisture buildup after rain.

- Musty odors are coming from the attic.

- Nails popping through shingles, indicating weakened wood beneath.

- Shingles that buckle, curl, or deteriorate due to compromised support.

- Light shining through the attic, showing gaps or holes in the decking.

- Pest damage, such as termite activity or chewed wood.

How Much Does Roof Decking Replacement Cost?

The table below provides a quick breakdown of the estimated costs for decking replacement based on roof size and typical price ranges.

| Roof Size (approx.) | Approx. # of Plywood/Decking Sheets* | Typical Total Cost Range (Installed) | Cost per Square Foot (Installed) |

|---|---|---|---|

| 500 sq ft | 15–20 sheets | US$1,000 – US$2,500 | US$ 2.00 – US$ 5.00 |

| 1,000 sq ft | 30–35 sheets | US$ 2,000 – US$ 5,000 | US$ 2.00 – US$ 5.00 |

| 1,500 sq ft | 45–50 sheets | US$3,000 – US$7,500 | US$ 2.00 – US$ 5.00 |

| 2,000 sq ft | 60–65 sheets | US$ 4,000 – US$ 10,000 | US$ 2.00 – US$ 5.00 |

| 2,500 sq ft | 75–80 sheets | US$ 5,000 – US$ 12,500 | US$ 2.00 – US$ 5.00 |

| 3,000 sq ft | 90–95 sheets | US$ 6,000 – US$ 15,000 | US$ 2.00 – US$ 5.00 |

| 3,500 sq ft | 115–120 sheets | US$ 7,000 – US$ 17,500 | US$ 2.00 – US$ 5.00 |

| 4,000 sq ft | 125–130 sheets | US$ 8,000 – US$ 20,000 | US$ 2.00 – US$ 5.00 |

Building Codes and Roof Decking Requirements

Building codes outline the minimum safety and structural standards for roof decking to ensure durability, load-bearing capacity, and weather resistance.

While specifics vary by region, most building codes follow guidelines from the International Residential Code (IRC) or local municipal codes.

Key Requirements Include:

1. Approved Materials: Roof decking must be made from code-approved materials such as plywood, OSB (oriented strand board), or engineered wood panels. Thickness requirements typically range from 7/16″ to 3/4″, depending on roof load and rafter spacing.

2. Proper Panel Thickness: Codes determine minimum thickness based on rafter spacing (commonly 16″ or 24″ on center). Wider spacing requires thicker panels for adequate support.

3. Fastening Rules: Specific nail size, spacing, and pattern are mandated, often 8d nails spaced 6 inches on edges and 12 inches in the field for secure attachment.

4. Ventilation Requirements: Adequate attic or roof ventilation must accompany roof decking to reduce moisture buildup, prevent rot, and maintain shingle warranty compliance.

5. Moisture Protection: Underlayment (felt or synthetic) is required over decking before shingles. In cold climates, ice-and-water shield may be mandatory along eaves.

6. Structural Load Compliance: Decking must support dead loads (materials) and live loads (snow, wind). Regions with heavy snow may require thicker decking or engineered panels.

7. Inspection Requirements: Roof decking must pass a framing inspection before roofing materials are installed to ensure panels are secure, undamaged, and properly spaced

Conclusion

Roof decking may not be the most glamorous part of your home, but it’s undeniably one of the most critical.

As we’ve seen, this foundational layer provides essential structural support, protects your home from the elements, and ensures the longevity of your entire roofing system.

Whether you’re planning a new roof installation or maintaining an existing one, never underestimate the importance of quality decking beneath those shingles.

Contact our experienced roofing professionals today for a comprehensive inspection and expert guidance tailored to your home’s unique needs!