Do your wheels match your vehicle’s bolt pattern?

Many car owners face a common problem: they buy new wheels only to find they don’t fit their car’s bolt pattern. It’s a costly mistake that leaves them with useless wheels and wasted money.

Here’s the good news: knowing about 5×4.5 bolt patterns can save you from this headache.

This guide will show you what these numbers mean, which cars use this pattern, and how to check if it’s right for your vehicle.

By the end, you’ll know exactly what to look for when buying wheels for your car.

Understanding the 5×4.5 Bolt Pattern & Its Measurements

What is the 5×4.5 Bolt Pattern?

A 5×4.5 bolt pattern has five lug holes spread in a circle on your wheel. The 4.5 refers to the diameter in inches between two lug holes across each other. Think of it as drawing a circle through the center of one lug hole to its opposite hole—that distance is 4.5 inches.

This setup helps spread the car’s weight equally across all five points where the wheel connects to your vehicle.

Why is it Also Known as 5×114.3 mm?

The 5×114.3 mm pattern is the same in metric measurements. Car makers worldwide use both systems: inches in the US and millimeters elsewhere. 4.5 inches equals 114.3 millimeters exactly.

Many wheel makers list both measurements to help buyers find the right fit, no matter where they shop.

Importance of Accurate Measurements

Getting the exact bolt pattern right keeps you safe on the road. Even small measurement errors can cause wheels to fit poorly or come loose. A perfect match between your wheels and vehicle prevents shaking, wear, and possible accidents.

Always double-check these numbers before buying new wheels – it’s better to measure twice than make a costly mistake.

Factors to Consider When Selecting Wheels with a 5×4.5 Bolt Pattern

Vehicle–Specific Requirements

| Vehicle Type | Weight Rating | Recommended Materials | Special Notes |

|---|---|---|---|

| Compact Cars | 1,000-1,200 lbs per wheel | Aluminum alloy | Focus on reduced weight for fuel efficiency |

| Mid-Size Sedans | 1,200-1,400 lbs per wheel | Aluminum alloy, Steel | Balance between comfort and performance |

| SUVs | 1,500-1,800 lbs per wheel | Steel, Heavy-duty alloy | Must handle higher vehicle weight |

| Light Trucks | 1,800-2,500 lbs per wheel | Steel, Forged alloy | Built for load capacity and durability |

| Performance Cars | 1,300-1,500 lbs per wheel | Forged aluminum | Designed for speed and handling |

Material and Weight Considerations

The choice between aluminum and steel wheels depends on your driving needs. Aluminum wheels typically weigh 15-25 pounds, making them ideal for better fuel use and handling. These wheels help your car stop and turn faster due to their lower weight.

They also let your suspension work better by reducing stress on parts.

Steel wheels weighing 25-35 pounds offer different benefits. They stand up well to rough roads, heavy loads, and tough conditions. Their simple design makes repairs easier and less costly.

Many drivers choose steel wheels for winter driving because they resist salt and damage from potholes.

Your budget matters, too. Aluminum wheels cost more upfront but can save money on gas over time. Steel wheels cost less to buy and fix, making them good for work vehicles.

Consider how you use your car – daily commuting suits aluminum wheels, while frequent off-road trips might need steel’s strength.

Aesthetic Preferences and Design

Wheels come in many finishes: polished, painted, or machined. Black wheels work well with any car color, while silver adds a classic look. Consider your car’s style and color when choosing. Spoke patterns vary too – from simple five-spoke designs to complex patterns.

Pick something that fits your car’s character.

Manufacturer and Aftermarket Compatibility

Check if your chosen wheels work with your car’s brakes and suspension. Some cars need special wheel shapes to fit over large brake calipers. Factory-approved wheels often cost more but guarantee a perfect fit.

If you pick aftermarket options, research brands known for quality and proper testing.

How to Install Wheels with a 5×4.5 Bolt Pattern

Tools and Preparations Needed

| Tool | Purpose | Important Specifications | Safety Notes |

|---|---|---|---|

| Floor Jack & Jack Stands | Lifting & supporting vehicle | Weight rating must exceed vehicle weight | Never work under car with only jack support |

| Torque Wrench | Precise lug nut tightening | Must match vehicle’s torque specs (usually 80-100 ft-lbs) | Calibrate yearly for accuracy |

| Socket Set | Removing/installing lug nuts | Common sizes: 17mm, 19mm, 21mm, 22mm | Check size before starting |

| Wheel Lock Key | Remove security lug nuts | Must match vehicle’s specific pattern | Store in safe, accessible place |

| Wire Brush | Clean mounting surfaces | Steel bristles recommended | Wear eye protection while using |

| Anti-seize Compound | Prevent stuck lug nuts | Small amount needed per stud | Don’t use on wheel locks |

| Work Gloves | Hand protection | Heavy-duty, good grip | Must allow finger movement |

| Wheel Blocks | Prevent vehicle rolling | Two blocks minimum | Place on opposite wheels |

| Lug Nut Alignment Tool | Guide wheel installation | Must match lug pattern | Use only for alignment |

Step-by-Step Installation Process

1. Safety First

Always start with a solid foundation. Park your car on flat concrete, not gravel or dirt. Pull the parking brake tight. Put automatic cars in park or manual cars in first gear. Place wheel blocks on both sides of the wheels that will stay on the ground. This keeps your car stable while you work.

2. Lifting the Vehicle

Find the proper lift point in your owner’s manual. Place the jack securely under this spot. Lift until the tire is off the ground. Put jack stands under the car’s frame. Lower the car onto the stands slowly. Never work under a car supported only by a jack.

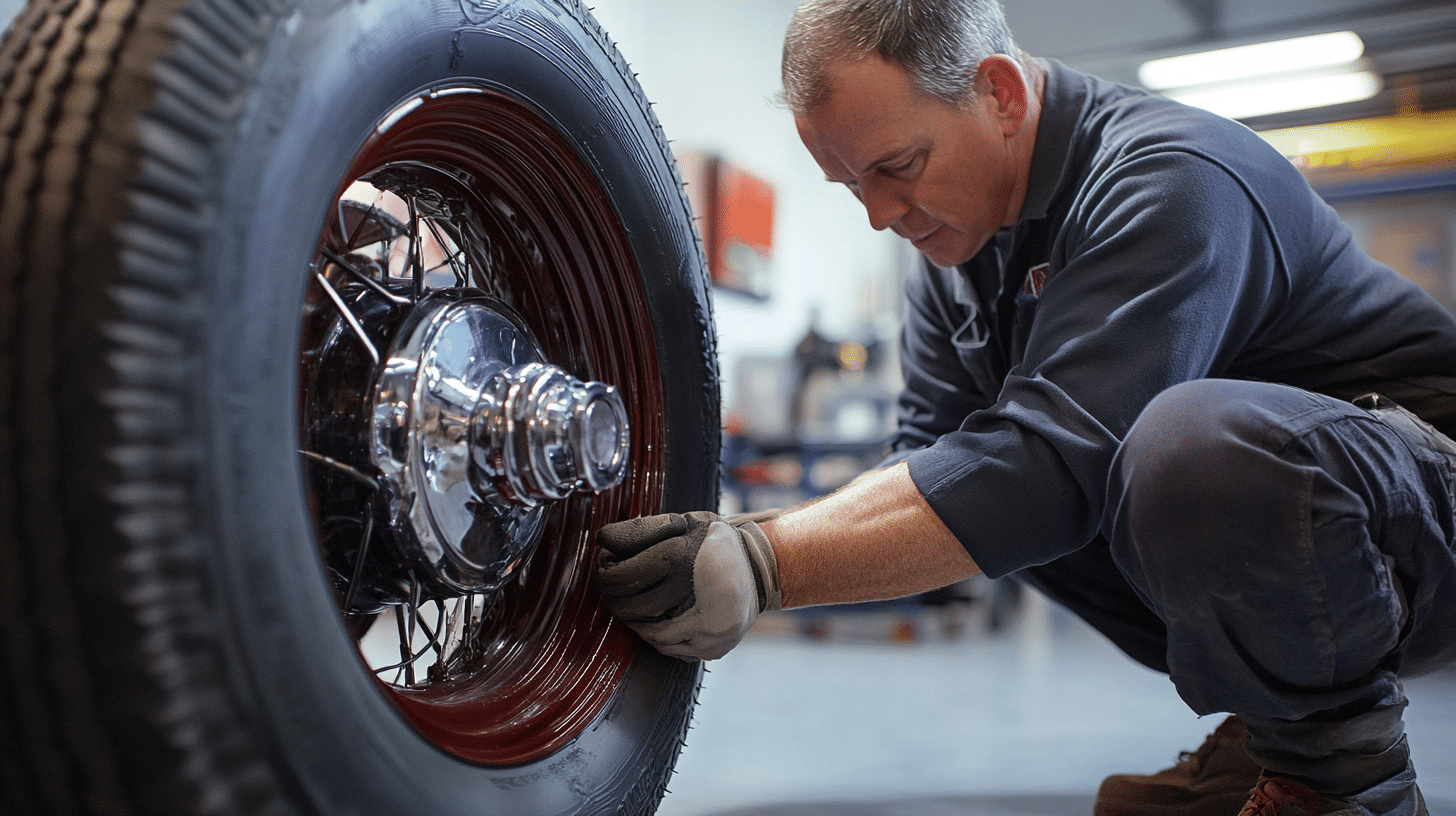

3. Remove Old Wheel

Break the lug nuts loose while the tire touches the ground – they’re easier to turn this way. Don’t remove them completely yet. Once loosened, lift the car and remove the nuts in a star pattern. Pull the wheel straight off. If stuck, tap gently with a rubber mallet.

4. Prepare for New Wheel

Clean the wheel hub with your wire brush. Remove any rust or dirt. Check the mounting surface for damage. Put a thin layer of anti-seize compound on the hub surface and lug studs. This prevents future rusting and makes the next removal easier.

5. Install New Wheel Line up the wheel

with the hub. Lift it straight on. Put all lug nuts on finger-tight. Start with the top nut, then move in a star pattern. Don’t fully tighten yet – just get them snug. Make sure the wheel sits flat against the hub.

6. Tightening Process

Lower the car until the tires just touch the ground. Use your torque wrench set to the right spec. Move in a star pattern. Tighten in three rounds: first at 30%, then 60%, then full torque. Never skip steps or rush this process. The pattern matters as much as the final tightness.

Post-Installation Checks

Safety checks are vital after installing your wheels. Start by driving slowly around your neighborhood at speeds under 30 mph. Pay attention to any pulling, shaking, or odd sounds. Your steering wheel should stay straight and steady.

Press the brake pedal – there should be no vibrations. Return home and check the lug nuts again – they should be tight. Look for any signs of wheel wobble or uneven wear. Schedule a follow-up check after 50 miles of driving to ensure everything stays secure.

Common Mistakes to Avoid During Installation

1. Incorrect Bolt Pattern Usage

Many wheel patterns look alike at first glance. The 5×4.5 pattern is often mixed up with 5×4.75 or 5×4.25 patterns. This small difference – just a quarter inch – can cause big problems. Wrong patterns mean wheels won’t sit properly on your car.

You might notice holes don’t line up exactly, or the wheel sits at an angle. Some people try to force-fit wheels or modify bolt patterns, which is dangerous. Always measure twice before buying. Use a bolt pattern gauge or measure between opposite lugs.

If you’re unsure, ask a professional to check your measurements.

2. Improper Lug Nut Tightening

The right amount of force matters when tightening lug nuts. Too tight can stretch or break bolts, strip threads, or warp your brake rotors. Too loose lets wheels move around, wearing out bolt holes and creating unsafe driving conditions.

Use a torque wrench set to your car’s specs. Tighten in a star pattern – never go around in a circle. Most cars need between 80-100 ft-lbs of torque. Start with hand-tight nuts, then use three stages of tightening to reach full torque.

Check the tightness again after 50 miles of driving.

3. Overlooking Wheel Offset

Wheel offset affects how your wheels sit in the wheel wells. Wrong offset pushes wheels too far in or out, causing problems with steering, suspension, and tire wear. Too much inward offset (positive) makes wheels rub against suspension parts.

Too much outward offset (negative) puts extra stress on wheel bearings. Your tires might also stick out past your fenders, which could be illegal. Check your car’s manual for the right offset numbers.

Consider both the offset and backspacing measurements when choosing new wheels.

4. Skipping Regular Maintenance

Regular wheel checks prevent problems. Check lug nut tightness monthly and after any wheel service. Look for cracks, bends, or damage to wheels. Clean your wheels to spot early signs of trouble. Watch for uneven tire wear – it might mean alignment issues.

Listen for new sounds when driving, like squeaks or rattles. If you hit a big bump or pothole, check your wheels right away. Keep records of when you last checked torque settings. Replace any damaged lug nuts or bolts immediately.

Take your car to a shop if you notice a steering wheel shake.

Applications of the 5×4.5 Bolt Pattern in Different Vehicles

Passenger Cars

The 5×4.5 bolt pattern appears in many everyday cars. Honda uses it in the Civic and Accord models. Toyota fits this pattern in the Camry and Corolla. These cars need wheels that handle daily driving well.

The pattern works with both 16-inch wheels for smooth rides and 18-inch wheels for better handling. Many automakers pick this size because it offers good strength without excess weight.

The pattern supports wheels wide enough for good road grip but not so wide that they waste fuel.

SUVs and Crossovers

Mid-size SUVs often use the 5×4.5 pattern. Both the Honda CR-V and Toyota RAV4 use this setup. These vehicles need stronger wheels that handle more weight.

The pattern works well with wheels from 17 to 19 inches. This size range gives SUVs the ground clearance they need. The five-bolt design spreads out the vehicle’s weight effectively.

This helps when carrying extra cargo or driving on rough roads.

Light Trucks

Smaller pickup trucks use this pattern often. The Nissan Frontier and older Ford Rangers fit this category. These trucks need wheels that handle both work and personal use.

The pattern supports wheel sizes from 15 to 18 inches. This range lets owners choose between road comfort and work capability. The five-bolt layout handles regular hauling tasks well.

Many owners use these trucks for both city driving and light off-road work.

Utility and Trailers

Many boat and camping trailers use 5×4.5 patterns. The pattern works well for loads up to 3,500 pounds per axle. Utility trailers need this strength for moving equipment and materials. The pattern fits both 14-inch and 15-inch trailer wheels.

These sizes work well for highway speeds and town use. The five-bolt design gives good safety margins for towing tasks.

Benefits of the 5×4.5 Bolt Pattern

Versatility Across Vehicle Types

The 5×4.5 bolt pattern works with many vehicle types, making it highly useful. Car makers choose this pattern for small cars, family sedans, and mid-size SUVs. It fits well on vehicles weighing from 2,500 to 6,000 pounds.

The pattern handles both city streets and country roads well. You can use these wheels on your daily work car and weekend camping trailer. This shared pattern means you can often swap wheels between different vehicles in your family.

The design suits both slow-speed city driving and highway speeds up to 80 mph. Its strength works for both light cars that need speed and heavier vehicles that carry loads.

Wide Availability of Options

You’ll find many wheel choices with the 5×4.5 pattern. Major brands offer wheels in sizes from 14 to 20 inches. Prices range from budget-friendly steel wheels to premium alloy options. Local stores usually keep these wheels in stock.

Online sellers offer even more choices. You can pick from simple designs or complex styles. The pattern fits both summer and winter tires. Many shops can service these wheels quickly.

You’ll find options in different colors, finishes, and price ranges. This variety helps you stay within your budget while getting the look you want.

Strength and Durability

The five-bolt design spreads out the weight and stresses very well. Each bolt handles about 20% of the force from driving. The 4.5-inch circle gives good support to the wheel’s center. These wheels often last 100,000 miles or more with proper care.

The pattern stays strong even when driving on rough roads. It handles the extra force from quick stops and fast turns. The design works well in both hot and cold weather. Salt and rain don’t usually cause problems.

The pattern keeps working well even after years of regular use. Many wheels show no signs of wear after 5-7 years of normal driving.

Ease of Customization

This pattern gives you many ways to change your car’s look. You can switch between different wheel widths and diameters. The pattern works with various wheel offsets for different looks.

You can pick thin or thick spokes based on your style. Many finish options exist – from basic black to bright chrome. You can match your wheels to your car’s color or create contrast. The pattern accepts many center cap styles and designs.

You can upgrade to bigger brakes without changing your bolt pattern. Tire choices range from street to off-road styles. This flexibility lets you update your car’s look whenever you want.

List of Vehicles Using the 5×4.5 Bolt Pattern

| Make & Model | Model Years | Wheel Width (inches) | Offset (mm) | Common Trim Levels |

|---|---|---|---|---|

| Honda Civic | 2006-2024 | 6.5-7.5 | +45 to +55 | LX, EX, Sport |

| Toyota Camry | 2002-2024 | 7.0-8.0 | +40 to +50 | LE, SE, XLE |

| Ford Mustang | 1994-2004 | 7.5-8.5 | +30 to +45 | Base, GT |

| Jeep Cherokee | 2014-2024 | 7.0-8.0 | +35 to +45 | Sport, Limited |

| Mazda CX-5 | 2013-2024 | 7.0-7.5 | +40 to +50 | Sport, Touring |

| Nissan Rogue | 2008-2024 | 7.0-7.5 | +40 to +45 | S, SV, SL |

| Subaru WRX | 2015-2024 | 7.5-8.5 | +45 to +55 | Base, Premium |

| Genesis Coupe | 2010-2016 | 8.0-9.5 | +35 to +45 | 2.0T, 3.8 |

| Tesla Model 3 | 2017-2024 | 8.0-9.0 | +35 to +45 | Standard, Long Range |

| Tesla Model Y | 2020-2024 | 8.5-9.5 | +35 to +45 | Standard, Performance |

| Ford Ranger | 1983-2011 | 6.0-7.0 | +25 to +35 | XL, XLT |

| Chevy S10 | 1994-2004 | 6.0-7.0 | +25 to +35 | Base, LS |

Conclusion

Understanding wheel bolt patterns can greatly impact your car care journey. The 5×4.5 pattern is a common choice across many vehicles, from family cars to light trucks. Its design combines strength and flexibility, making it a trusted option for many car makers.

When you know your bolt pattern, you save time and money on wheel shopping.

You avoid buying wheels that don’t fit, and you can focus on what matters – style, performance, and value. The right fit means safer drives and better performance.

Remember, the details matter when working with wheels. Take time to measure, check your specs, and follow proper installation steps.

Let me know if you have any questions about what we’ve discussed in this guide.