Have you ever found yourself confused by the numbers and measurements when finding the right wheels for your car?

You’re not alone. Many people struggle to understand wheel bolt patterns, especially the 5×112 pattern.

But don’t worry, we’ve got you covered. In this beginner’s guide, we’ll break down everything you need to know about the 5×112 bolt pattern.

What it means, which vehicles commonly use it, and how to ensure a perfect fit for your car.

By the end of this article, you will clearly understand this essential aspect of wheel fitment, enabling you to make informed decisions when upgrading your wheels.

Let’s dive in and demystify the 5×112 bolt pattern together!

Understanding 5×112 Wheel Bolt Patterns

A wheel bolt pattern is the specific arrangement of holes on a wheel corresponding to the lugs on a vehicle’s hub. This configuration allows the wheel to be securely fastened to the car.

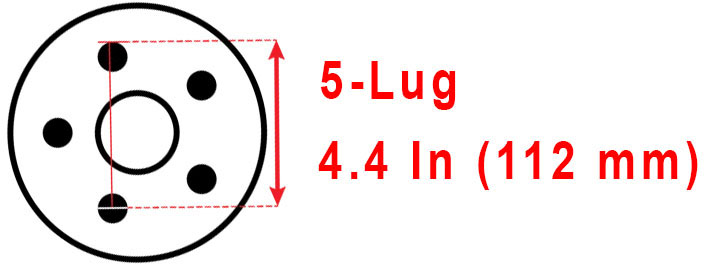

Bolt patterns are typically expressed using two numbers. First, it indicates the number of bolts.

The second one represents the diameter (in millimeters or inches) of the imaginary circle formed by the center of these bolts.

Importance of Matching Bolt Patterns

Ensuring that your wheels have the correct bolt pattern for your vehicle is crucial for several reasons:

- Safety: A properly matched bolt pattern guarantees a tight fit between the wheel and the hub. It minimizes the risk of wheels coming loose or detaching while driving, which could lead to accidents.

- Compatibility: Using wheels with the right bolt pattern ensures proper alignment with your vehicle’s hub. It maintains the balance and handling characteristics as intended by the manufacturer.

- Performance: Selecting wheels with the correct bolt pattern improves vehicle performance. It includes even tire wear, smooth ride quality, and overall drivability.

Components of a Bolt Pattern

- Number of Bolts: The number of bolts in a pattern usually ranges from 4 to 8. Generally, a higher number of bolts is associated with vehicles designed for higher performance or heavier loads. The additional bolts provide greater strength and stability.

- Pitch Circle Diameter (PCD): The PCD is the diameter of the imaginary circle formed by the center of the bolt holes. It is measured from the center of one bolt hole to the center of the bolt hole directly across from it.

Calculating PCD

For bolt patterns with an even number of bolts (4, 6, or 8), the PCD can be calculated using the following formula:

PCD = Distance between opposite bolts × √2 / 2

Here’s an example calculation for the 5×112 bolt pattern:

Measure the distance between the center of one bolt hole and the center of the bolt hole farthest away from it.

Let’s say this distance is 6.93 inches.

PCD = 6.93 inches × √2 / 2

= 6.93 inches × 0.7071

= 4.90 inches (or approximately 112mm)

Understanding PCD is essential when selecting new wheels, replacing damaged ones, or upgrading your rims.

1. Application to 5×112

The 5×112 bolt pattern is commonly found on European vehicles such as Audi, Volkswagen, and Mercedes-Benz. It consists of five equally spaced bolt holes on a circle with a diameter of 112mm. Some popular models using this pattern include the Audi A4, Volkswagen Golf, and Mercedes-Benz C-Class.

Knowing your vehicle’s bolt pattern, such as 5×112, can save you time and money when maintaining or customizing it.

For example, when replacing a damaged wheel or upgrading to aftermarket rims, ensure the new wheels have the correct 5×112 bolt pattern. It will guarantee a proper fit without needing adapters or modifications, preventing potential issues.

2. Comparative Table of Bolt Patterns

Here is a table comparing different common bolt patterns and their uses across various vehicle types:

| Bolt Pattern | Common Vehicle Types |

|---|---|

| 4×100 | Compact cars (Honda Fit, Mazda2), subcompacts |

| 5×112 | Mid-size sedans (Audi A4, VW Passat), luxury SUVs (Mercedes-Benz GLE) |

| 6×135 | Heavy-duty trucks (Ford F-150), commercial vehicles |

Focus on The 5×112 Bolt Pattern

The 5×112 bolt pattern is a specific wheel configuration featuring five equally spaced bolts. They are arranged in a circular pattern with a diameter of 112 millimeters.

This bolt pattern is most commonly found on European vehicles, as it provides a secure and stable connection between the wheel and the vehicle’s hub.

Vehicles Using 5×112

Many popular European vehicle models, including the Audi A4, A6, Q5, and Q7, utilize the 5×112 bolt pattern.

Volkswagen: Passat, Tiguan, Golf

Mercedes-Benz: C-Class, E-Class, GLK

These vehicles are often preferred by drivers who value high performance, safety, and reliability.

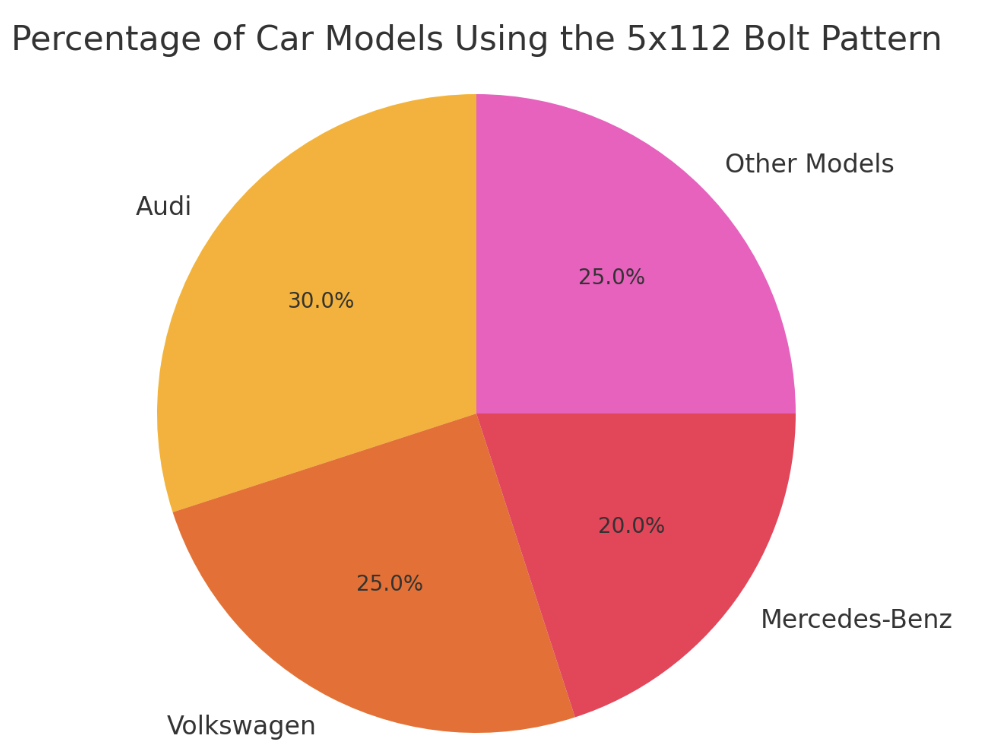

Pie Chart of Car Model Distribution

Here is a pie chart depicting the percentage of car models using the 5×112 bolt pattern.

It shows the distribution across brands like Audi, Volkswagen, and Mercedes-Benz, compared to other models.

Advantages of Using 5×112

1. Stability and Fit

One key advantage of the 5×112 bolt pattern is its exceptional stability. The even distribution of the five bolts around the wheel hub ensures a balanced and secure fit.

This snug and precise connection between the wheel and the hub enhances the vehicle’s handling and minimizes the risk of wheel vibration or detachment.

2. Availability and Compatibility

European vehicle manufacturers’ widespread use of the 5×112 bolt pattern makes it readily available in the aftermarket wheel industry.

This makes it easier for vehicle owners to find replacement wheels or upgrade their existing ones.

Additionally, the 5×112 pattern’s compatibility across multiple vehicle brands means drivers have wider wheel options.

3. Performance

The 5×112 bolt pattern is designed to support high-performance driving characteristics. The five bolts’ even distribution helps spread the load evenly across the wheel.

It reduces stress on individual bolts and minimizes wheel and tire wear. This balanced load distribution improves cornering stability, acceleration, and braking performance.

The 5×112 pattern is ideal for drivers who prioritize a dynamic and responsive driving experience.

Choosing and Fitting 5×112 Wheels

Selecting the Right Wheels

1. Guide on Choosing Wheels

When selecting wheels for vehicles with the 5×112 bolt pattern, it’s crucial to ensure they are specifically designed for this configuration.

While the 5×112 pattern is common among many European vehicle models, it’s always best to refer to the manufacturer’s specifications to guarantee compatibility and optimal performance.

2. Key Considerations While Selecting the Wheel Size

When choosing wheels, it is essential to match the wheel diameter, width, and offset (backspacing) to your vehicle’s requirements.

The correct wheel size ensures proper fitment, maintains vehicle handling and prevents clearance issues.

Consult your vehicle’s owner manual or a trusted wheel specialist for guidance on the appropriate wheel size.

3. Material Selection

- Steel Wheels: They are Known for their durability and affordability. Steel wheels are an excellent choice for off-road adventures or heavy-duty applications. They are less likely to crack or break under stress and can withstand impacts better than alloy wheels. However, steel wheels are heavier, which can slightly affect vehicle performance.

- Alloy Wheels: Made from a mixture of metals. Alloy wheels offer a lighter-weight alternative to steel wheels. This weight reduction can improve vehicle handling, acceleration, and fuel efficiency. Additionally, alloy wheels provide a more visually appealing option with various designs.

4. Aesthetics

It’s also important to consider the aesthetic appeal of your chosen wheels. Select a wheel design that complements your vehicle’s overall appearance. consider factors such as color, spoke design, and finish.

However, always prioritize compatibility and functionality over aesthetics to ensure a safe and reliable driving experience.

Step-by-Step Installation Tips

- Preparation: Before installing your new 5×112 wheels, thoroughly inspect them for any defects or damage. Ensure that all the bolts and hub components are in good condition and free from rust. Clean the hub and wheel mounting surfaces to ensure a proper and secure fit.

- Alignment: Position the wheel evenly on the hub. Make sure that the bolt holes are aligned. Hand-tighten each bolt in a star pattern (alternating between opposite sides) to ensure preliminary alignment and even pressure distribution.

- Balancing: After installation, have a professional balance of your wheels to minimize vibrations and uneven tire wear at higher speeds. This process involves adding small weights to the wheel to counteract any imbalances.

- Securing Bolts: Using a torque wrench, tighten the bolts to the manufacturer’s recommended specification. Follow a star pattern when tightening to distribute the tension evenly across the wheel. Avoid over-tightening, as this can lead to bolt failure or damaged threads.

Common Pitfalls and How to Avoid Them

- Over-Tightening: Applying too much torque when tightening the bolts can cause damage to the bolts, wheels, or hub. Always use a torque wrench set to the manufacturer’s recommended value to prevent over-tightening.

- Improper Alignment: Misaligned wheels can cause uneven tire wear, poor handling, and increased strain on suspension components. Regularly check and adjust your wheel alignment to maintain optimal performance and safety.

- Inadequate Bolt Length: Using too short or too long bolts for your specific wheel and hub combination can compromise the wheel’s securement. It can lead to safety issues. Ensure that you use the correct bolt length as the wheel or vehicle manufacturer specified.

Maintenance and Troubleshooting

Regular Maintenance

To ensure the longevity and optimal performance of your 5×112 wheels, it’s crucial to perform regular maintenance.

Periodic checks every few months can help identify early signs of damage or wear, allowing you to address issues before they become more serious.

By following a consistent maintenance routine, you can extend the life of your wheels and maintain a safe driving experience.

Key Maintenance Tips

- Cleaning: Regularly clean your wheels using non-abrasive cleaning solutions and soft brushes to remove brake dust, dirt, and grime. Avoid using harsh chemicals or abrasive materials that can damage the wheel finish. For alloy wheels, use a pH-neutral cleaner specifically designed for this material. Steel wheels can be cleaned with mild soap and water, followed by a protective wax coating to prevent rust.

- Inspection: During each cleaning session, take the time to inspect your wheels thoroughly. Check the wheel surface and bolts for any signs of corrosion, cracks, or dents. Ensure that the wheel hub is not warped and that all bolts are securely fastened. If you notice any damage or irregularities, address them promptly to prevent further deterioration.

- Seeking Professional Help: If you experience vibrations, unusual sounds, or wheel wobbling while driving. Consult a professional mechanic. These symptoms could indicate issues with wheel alignment, balance, or bearing problems. Regular tire rotations and balancing can also help ensure even tire wear and maintain optimal handling characteristics.

Troubleshooting Common Issues

Using wheels with a mismatched bolt pattern can lead to serious safety issues. Attempting to force a wheel with an incorrect bolt pattern onto your vehicle’s hub can cause damage to the wheel, bolts, and hub.

In extreme cases, this can result in wheel detachment while driving, putting yourself and others at risk.

Common Problems

1. Loose Bolts

- Symptoms: If you notice vibrations, rattling noises, or a feeling of instability while driving, your wheel bolts may be loose.

- Solution: Using a torque wrench, re-tighten the bolts to the manufacturer’s specified torque values. Check the bolts periodically to ensure they remain properly tightened.

2. Misalignment

- Symptoms: Uneven or rapid tire wear, a steering wheel that pulls to one side, or a vibration in the steering wheel can all indicate misaligned wheels.

- Solution: Have your wheels professionally aligned to ensure they are positioned correctly on the hub and pointing in the proper direction.

3. Damaged Bolt Holes

- Symptoms: If the bolts no longer fit snugly into the wheel’s bolt holes or if you notice signs of elongation or deformation around the holes, the bolt holes may be damaged.

- Solution: Replace the affected wheel immediately. Continuing to use a wheel with damaged bolt holes can compromise the wheel’s structural integrity and increase the risk of accidents.

4. Corrosion

- Symptoms: Rust or oxidation on the wheel surface or around the bolt holes can weaken the wheel and cause aesthetic issues.

- Solution: Clean the affected areas with a rust removal solution appropriate for your wheel material. After removing the corrosion, apply an anti-corrosion coating to protect the wheel from future damage.

By following these maintenance guidelines and promptly addressing any issues, you can ensure the safety, longevity, and performance of your 5×112 wheels.

Technological Developments

Advances in Manufacturing and Design

The wheel industry has undergone significant transformations. All thanks to modern manufacturing techniques like computer-aided design (CAD) and 3D printing.

These advancements have revolutionized the production process. They have enabled manufacturers to create wheels with highly precise bolt patterns that were previously unattainable.

Specific Manufacturing Processes that Have Had a Notable Impact Include

- Flow Forming: This process combines casting and forging techniques to create lightweight yet strong wheels. The wheel is cast and then spun on a mandrel while pressure is applied to the rim area. This results in a wheel with improved grain structure and strength-to-weight ratio.

- Forging: Forged wheels are created by applying immense pressure to a solid aluminum alloy block. It creates a dense, strong, and lightweight wheel. Forged wheels offer superior strength and reduced weight compared to traditional cast wheels.

Impact on 5×112 Patterns

- Customization: Advanced manufacturing techniques have opened up new possibilities for customizing 5×112 wheel patterns to suit specific vehicle specifications. Manufacturers can now produce wheels with unique spoke designs, finishes, and offsets while maintaining the precise 5×112 bolt pattern.

- Lightweight Materials: The use of advanced alloys and carbon fiber in wheel production has enabled the creation of lightweight wheels. These materials help reduce overall vehicle weight, improving fuel efficiency and performance.

- Safety and Performance: Precision manufacturing ensures that 5×112 wheels are produced to exact specifications. This results in improved safety, balance, and performance. This is particularly crucial for high-performance vehicles that demand optimal wheel fitment and stability.

Future Trend of Changing Vehicle Design

- Electrification and Autonomous Vehicles: As the automotive industry shifts towards electric vehicles (EVs) and autonomous cars. The wheel design is also likely to evolve. Lightweight wheels with precise bolt patterns, such as 5×112, will become increasingly important to maximize efficiency and reduce wear on EV powertrains. The reduced weight will also help extend the range of EVs.

- Growth in SUVs and Crossovers: The popularity of larger vehicles like SUVs and crossovers is expected to continue growing. This trend will likely lead to an increased demand for 5×112 bolt patterns due to their versatility and ability to support the weight and performance requirements of these larger vehicles.

Innovations in Materials

The emergence of new materials, such as graphene composites or next-generation alloys, could revolutionize wheel production.

These materials may enable manufacturers to create even stronger and lighter wheels. As material science advances, we can expect to see wheels that push the boundaries of strength, durability, and weight reduction.

Regulatory Changes

Future changes in emissions and safety regulations may influence wheel design and standardization. As vehicle manufacturers strive to meet these evolving standards, they may gravitate towards standardizing certain bolt patterns, like 5×112.

This standardization will help streamline compliance and simplify production logistics, leading to increased availability and compatibility of 5×112 wheels across a broader range of vehicles.

Conclusion

Understanding the 5×112 bolt pattern is crucial for anyone looking to upgrade or replace their vehicle’s wheels.

By familiarizing yourself with the basics of bolt patterns, the advantages, and the process of selecting and installing compatible wheels, you can ensure a safe and successful wheel upgrade.

Remember to prioritize proper fitment, consider your vehicle’s unique requirements, and follow the recommended maintenance practices to keep your wheels in top condition.

As technology advances, the world of wheels and bolt patterns is set to evolve. It offers exciting new possibilities for customization and performance.

By staying informed and adapting to these changes, you can maximize your vehicle’s potential and enjoy a smooth.

Happy driving!