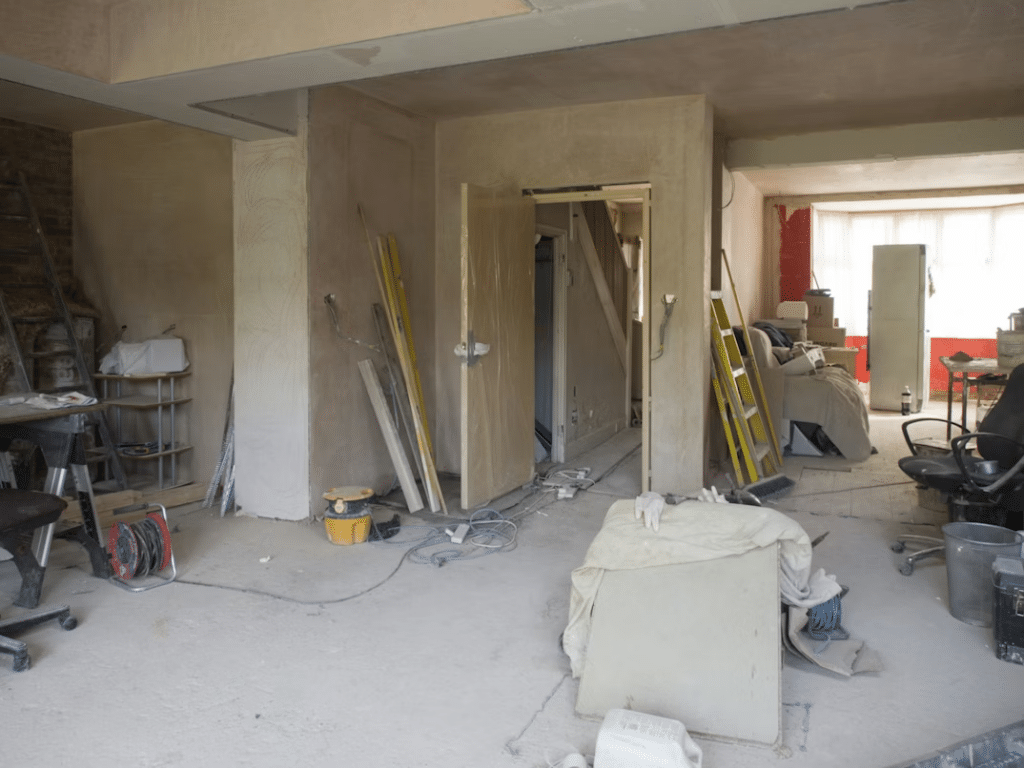

Major structural updates are not like swapping cabinets or repainting a room. The work can touch safety, permits, and the long-term value of the building. Picking the right partner is mostly about reducing surprises, not chasing a perfect plan.

Start with a clear scope and real constraints

Write down what is changing and why it matters. If a wall is moving, a roofline is shifting, or a foundation needs repair, treat it like a systems problem, not a single task.

Bring photos, rough measurements, and any past plans to the first meetings. Note what is non-negotiable, like keeping a staircase in place or protecting a historic feature, so the team does not design around the wrong assumptions.

List the limits that will shape every decision, like the budget range, move-out dates, noise rules, and access to the site. A practical partner will ask about these early since they affect the schedule, sequencing, and risk.

Prioritize end-to-end coordination, not just labor

Structural projects usually involve design choices, engineering input, permits, and multiple trades working in a tight order. The more handoffs there are, the easier it is for details to get lost.

Structural work often fails at the seams, where design, permits, and field conditions meet. When the job affects load paths, a full-service construction company that coordinates planning, permitting, and execution can reduce gaps between what is drawn and what gets built. That single line of responsibility makes it easier to track accountability when something changes midstream.

Ask who will be the day-to-day point person and how decisions get documented. A practical setup includes a single channel for questions, a running list of approvals, and a clear rule for when work pauses until a decision is made.

Vet the basics: license, insurance, and safety habits

Before talking finishes or upgrades, confirm the legal and safety fundamentals. A practical partner should be comfortable showing documentation and explaining who is covered on-site.

A house renovation guide from The Spruce notes that it is smart to verify an active state license and confirm liability coverage plus workers’ compensation, since those protect both the homeowner and the crew. That simple check can filter out operators who disappear when problems show up.

Beyond the paperwork, listen to how they talk about safety. Strong teams describe shutoff planning, dust control, and how they handle surprises like hidden wiring or old plumbing without turning the site into chaos.

Compare bids by asking the same questions

Bids are only comparable when they describe the same scope, assumptions, and quality level. If one proposal includes structural engineering coordination and another does not, the lower number can be misleading.

Architectural Digest recommends meeting with at least 3 contractors so you can calibrate pricing and get a feel for how each one manages a build. Use those conversations to standardize what you request, like this:

- A line-item scope that calls out what is included and excluded

- A realistic schedule with key milestones and decision points

- The names of major subs and who supervises them

- Allowances that list unit costs and selection deadlines

- A plan for protecting the home, neighbors, and existing finishes

After you have the bids, review the exclusions and assumptions line by line. If something feels vague, ask for it in writing, since small wording gaps can become big cost gaps once work is underway.

Lock down change orders before the first demo

Even a well-scoped structural update can change once walls open up. The practical move is to decide, in writing, how changes will be priced and approved before the project starts.

A construction-law article from Dufault Law describes change orders as the written record that supports modifications to the original agreement, which is why they matter when scope shifts. Treat every change like a mini-contract with the what, the cost, the time impact, and the signature.

Set simple guardrails, like no work on changes without a signed form and a clear price. Keep a running log so it is easy to see how each change affects the total, instead of finding out at the end.

Watch for strong communication and steady site discipline

Good partners communicate in patterns, not bursts of reassurance. Look for clear meeting notes, fast answers to questions, and a simple way to track open items without losing them in texts.

Pay attention to jobsite order, too, since it often mirrors project management. If materials are staged logically and the crew follows a predictable routine, that same discipline tends to show up in scheduling and quality control.

Ask what a normal week looks like, including check-ins, photo updates, and who attends walkthroughs. When responsibilities are clear, the project stays calmer, even when the building reveals something unexpected.

Major structural updates can go smoothly when the right partner brings clarity, coordination, and solid paperwork. If you vet credentials, compare bids on the same scope, and lock down change orders early, you reduce the biggest causes of cost jumps and delays. The goal is not perfection – it is a steady process where decisions are documented, and the job stays under control.