Getting new wheels for your car should be exciting, not confusing.

As a mechanic with 15 years of experience, I’ve seen many car owners waste money on wheels that don’t fit because of one small detail: the center bore.

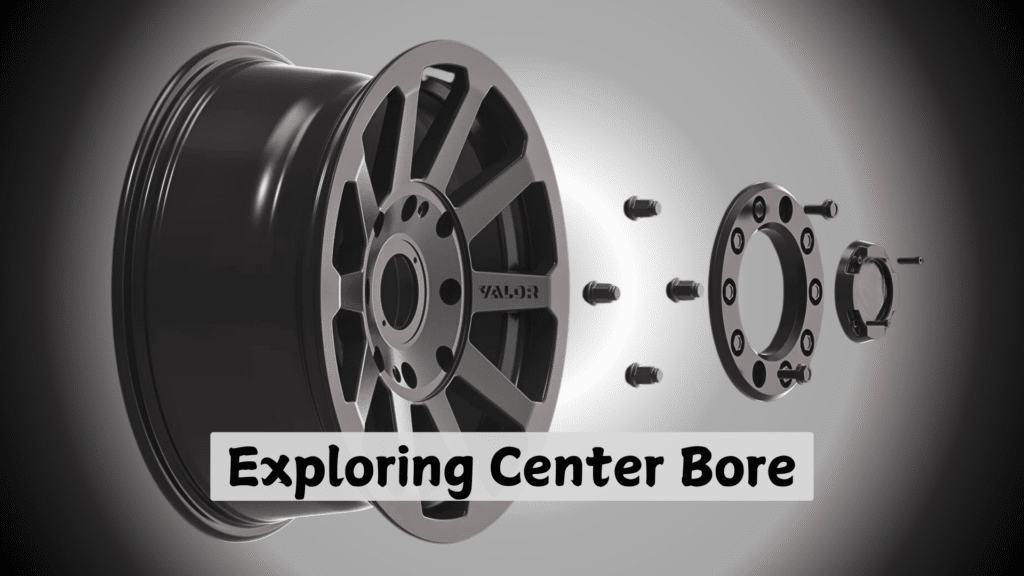

The center bore is the hole in the middle of your wheel that fits onto your car’s hub.

Getting this wrong can lead to vibration, poor handling, and safety issues.

In this article, you’ll learn:

- What center bore means in simple terms

- How to measure it correctly

- Common problems and their fixes

I’ve tested hundreds of wheel fitments and made every mistake possible.

Now, I’ll help you avoid these errors and choose the right wheels the first time.

Let’s get your wheels fitted properly.

What is Center Bore and Why It Matters?

The center bore is like a guide pin – it’s the round hole in the middle of your wheel that fits over your car’s hub.

Think of it as putting a ring on your finger – it needs to be the right size to fit well.

Let me explain why this matters to you:

When you drive, your wheels spin at high speeds.

The center bore helps keep them perfectly centered.

Without proper centering, three things can go wrong:

- Your wheels might wobble

- Your tires could wear unevenly

- Your car’s handling could get worse

Here’s a simple test: Grab a plate and try spinning it on a table while it’s slightly off-center.

Notice how it wobbles?

That’s what happens to your wheels with an incorrect center bore fit.

I often tell my customers: lug nuts hold your wheel on, but the center bore keeps it steady.

It’s like having a steady hand when writing – you need both the grip and the balance.

The right fit means:

- Smooth rides

- Even tire wear

- Better handling

- Safer driving

Remember: A wheel with the wrong center bore is like wearing shoes that don’t fit.

They might look good, but they’ll cause problems down the road.

How to Measure Center Bore Correctly?

You’ll need these basic tools

- Digital caliper (I recommend a plastic one to avoid scratches)

- Clean cloth or rag

- Flashlight

- Notebook for measurements

Let’s measure your center bore in 4 simple steps:

Step 1: Clean the Area

First, wipe the hub and wheel center clean.

Dirt or rust can mess up your measurements.

I learned this the hard way after getting wrong readings from a dirty hub.

Step 2: Get Your Caliper Ready

Open the caliper wide enough to fit around the center hole.

Make sure the jaws are clean and move smoothly.

If they stick or feel rough, your measurements won’t be accurate.

Step 3: Take the Measurement

For the wheel:

- Place the caliper’s jaws inside the center hole

- Gently expand until they touch both sides

- Read the number in millimeters

- Take three measurements and write them down

For the hub:

- Measure the raised center section

- Take measurements at different points

- Write down all numbers

Step 4: Check Your Work

The hub measurement should be slightly smaller than the wheel’s center bore.

I usually aim for a difference of 0.1 to 0.5 millimeters.

Pro tip: If you get different numbers each time, you’re probably not measuring straight across.

Try again, keeping the caliper level.

Watch out for these common mistakes:

- Measuring a dirty or rusty surface

- Using worn-out calipers

- Measuring at an angle

- Forgetting to write down the numbers

Common Issues with Center Bore

1. Wrong Size Matching

I’ve fixed countless wheels that didn’t fit right because the center bore was too big or too small.

When the hole is too big, your wheel sits off-center.

This makes your car shake at higher speeds.

If it’s too small, you can’t even mount the wheel properly.

2. Hub Rings Coming Loose

Some folks use plastic hub rings to make wheels fit.

While these work, they can break down over time.

I once had a customer come in with bad vibrations – their hub ring had cracked in half.

Metal rings last longer, but they need proper installation.

3. Rust Build-up

Your hub can rust over time.

This rust builds up and makes the center bore fit too tight.

Last week, I spent two hours helping a customer who couldn’t remove their wheels because of rust.

Regular cleaning prevents this problem.

4. Uneven Wear Patterns

When your center bore doesn’t match perfectly, your tires wear unevenly.

I check tire wear patterns to spot center bore issues.

If you see more wear on one side of your tire, your wheel might not be centered properly.

5. Vibration at Speed

This is the most common problem I see.

A bad center bore fit causes vibrations that get worse as you drive faster.

You might feel it in your steering wheel first.

Then it spreads to the whole car.

6. Installation Damage

Forcing a wheel onto a hub that’s too big or too small can damage both parts.

I’ve seen scratched hubs and cracked wheel centers from people trying to make mismatched parts fit.

7. Balance Problems

Your wheels won’t balance right with a poor center bore fit.

You can add all the weights you want, but if the wheel isn’t centered, it won’t spin true.

I always check the center bore before starting any wheel balance job.

8. Safety Risks

Bad fits create unsafe driving conditions.

Your wheels could shake loose or cause you to lose control.

This isn’t just about comfort – it’s about keeping you safe on the road.

Fix-it tip: Keep your hub clean and measure twice before buying new wheels.

If you need hub rings, spend extra on quality metal ones.

They cost more upfront but save money in the long run.

Center Bore in Different Types of Wheels

Let me break this down into a simple comparison table based on my experience working with different wheels.

| Wheel Type | Center Bore Details | What You Need to Know |

|---|---|---|

| Factory Alloy |

• Exact match to your car • Usually 54-74mm • High-quality finish |

• Fits perfectly without rings • Best option for direct fit • Often more expensive |

| Aftermarket Alloy |

• Larger holes (often 72-74mm) • Needs hub rings • Various finishes |

• Requires correct hub rings • Check ring quality • More wheel options available |

| Steel Wheels |

• Simple design • 70mm common size • Basic finish |

• Good for winter tires • Less sensitive to fit • Most cost-effective |

| Racing Wheels |

• Specific sizes • Tight tolerances • Special materials |

• Need exact measurements • No room for error • Regular checking needed |

| Universal Fit |

• Larger bore size • 73.1mm common • Needs hub rings |

• Always needs hub rings • Check ring quality • More prone to fit issues |

Remember: These numbers are general guides.

Always measure your specific car’s hub before buying new wheels.

Tips for Choosing the Right Center Bore

1. Check Your Car’s Manual First

I always tell my customers to start with their car’s manual.

It’s the most reliable source for your hub size.

Car makers put this information there for a reason.

When you can’t find your manual, look under your hood for a specs sticker.

These stickers often have wheel information.

2. Measure Twice, Buy Once

Take measurements twice at different times.

Temperature changes can affect metal sizes slightly.

Write down both measurements. If they match, you’re on the right track.

If they don’t, measure again.

This small step saves both time and money.

3. Contact the Wheel Maker

I’ve learned that good wheel companies know their products well.

Call them with your car’s make, model, and year.

They can tell you if their wheels will fit your car.

They might even know about common problems with your specific model.

4. Consider Hub Rings

If you find wheels you like but their center bore is too big, don’t worry.

Hub rings can help.

But remember: metal rings last longer than plastic ones. I’ve replaced hundreds of broken plastic rings.

Spend a bit more on metal ones – they’re worth it.

5. Look at Your Driving Needs

Think about how you use your car.

Daily commuter? Weekend cruiser?

This matters.

Highway driving needs better fit than city driving.

More speed means you need better centering.

I tell my track day customers to stick with exact fits, no rings if possible.

6. Get a Test Fit

Many shops will test-fit wheels before you buy.

This service might cost a little, but it’s cheaper than buying wrong wheels.

I offer free test fits because I’d rather help customers get it right the first time.

7. Keep Your Records

Save your measurements, receipts, and specs.

You’ll need these if you ever want to sell your wheels or buy new ones.

I keep a small notebook just for wheel specs.

It has saved me lots of time over the years.

8. Plan for Winter

If you live where it snows, remember that winter affects wheel fit.

Salt and ice can damage hub rings.

Make sure your winter set has the right center bore too.

This is especially true for steel winter wheels.

Conclusion

Getting your center bore right makes all the difference in how your wheels perform.

As a mechanic, I’ve seen both the good and bad results of wheel fitting.

Remember these key points:

- Measure carefully before buying

- Keep your specs handy

- Use quality hub rings when needed

The right fit means a smoother ride, longer-lasting tires, and better handling.

More importantly, it keeps you safe on the road.

From my years in the shop, I can tell you that spending time on proper wheel fitting saves money in the long run.

No more fixing vibration issues or replacing worn tires early.

Take your time, do it right, and enjoy the ride.

Want more help? Drop a comment below with your car’s make and model.

I’ll help you find the right fit.

Frequently Asked Questions

Can I Drive With A Slightly Mismatched Center Bore?

While possible, it’s not safe.

Even small mismatches cause vibrations that damage your wheels, tires, and suspension over time.

Always get the correct fit.

Do All Hub Rings Need To Be The Same Thickness?

Yes.

Using different thickness hub rings will throw your wheel off-center.

This causes dangerous vibrations and uneven tire wear.

Will Weather Changes Affect My Hub Rings?

Metal hub rings work well in all weather.

Plastic rings can crack in extreme cold and get soft in high heat.

Choose metal for year-round use.