Walking into a hardware store can feel overwhelming. Rows of plywood sheets stare back, each claiming to be the perfect choice.

But not all plywood is created equal. Marine plywood, commercial plywood, flexible plywood; the options seem limitless, and picking the wrong one could mean wasted money or a failed project.

Homeowners and DIY fans often struggle with this exact problem. They need clarity on what makes each type different and which one actually fits their needs.

This blog breaks down the most common types of plywood, explaining their key features in simple terms so anyone can make a smart choice.

Which Type of Plywood Should You Use for Your Project?

Choosing the right plywood isn’t just about grabbing the first sheet that fits the budget.

Different projects demand different qualities. A kitchen cabinet needs moisture resistance, while furniture requires a smooth finish. Outdoor structures? They need something that can handle rain and sun without falling apart.

Using the wrong type can lead to warping, cracking, or costly repairs down the line.

Understanding what each plywood type offers helps match the material to the job. From marine-grade sheets to commercial boards, readers will learn which option works best for specific applications.

What are the Different Types of Plywood?

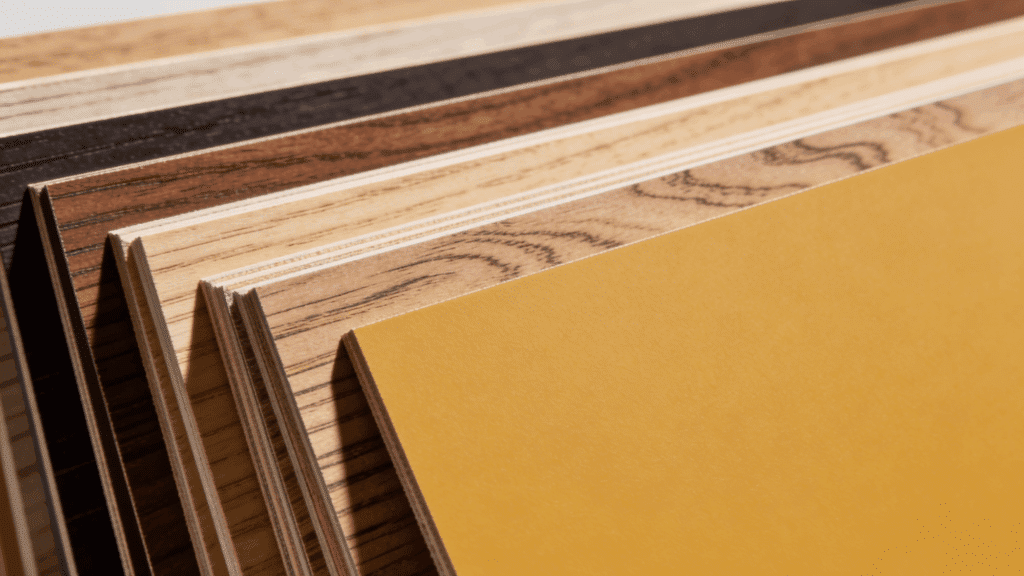

Different plywood types vary by wood species, layer count, and resistance level, helping builders and homeowners choose the right material.

By Wood Type

Plywood types differ based on the wood veneers used, affecting durability, appearance, and best applications for furniture, construction, or cabinetry.

1. Hardwood Plywood

Hardwood plywood is made from oak, birch, or teak veneers. It offers excellent strength, smooth finishing, and long-lasting durability.

Commonly used in furniture, cabinetry, and premium interior projects where appearance and toughness matter most.

2. Softwood Plywood

Softwood plywood comes from pine or spruce veneers. It is affordable, lightweight, and widely used in construction work like roofing, wall sheathing, and subfloors.

It provides good structural support while remaining cost-effective for large building projects.

3. Baltic Birch Plywood

Baltic birch plywood features all-birch layers with a void-free core.

It is extremely strong, stable, and ideal for high-quality furniture, drawers, and detailed woodworking projects. Its uniform layers make it popular for precision cutting and durable designs.

By Layer Count

Layer count determines plywood strength, flexibility, and load capacity, making it suitable for lightweight panels or heavy-duty structural projects.

4. Three-Ply

Three-ply plywood consists of three veneer layers, making it flexible and lightweight.

It is often used for simple DIY projects, decorative panels, and interior applications where heavy load support is not required but ease of handling matters.

5. Five-Ply

Five-ply plywood is stronger and more stable than three-ply. It is commonly used in cabinets, furniture bases, and moderate-load construction projects.

The additional layers improve durability while still keeping the sheet manageable and versatile.

6. Multi-Ply

Multi-ply plywood has eight or more veneer layers, giving it superior strength and thickness.

It is best for heavy structural uses such as roofing, industrial flooring, and high-load construction. Its layered build ensures long-lasting stability under pressure.

By Resistance/Use

Some plywood types are specially treated for moisture, water, or heavy-duty environments, ensuring performance in kitchens, outdoors, or marine settings.

7. MR (Moisture Resistant) Plywood

Moisture-resistant plywood is designed for interior spaces exposed to humidity, such as kitchens, shelves, and wardrobes.

It resists minor moisture but is not fully waterproof. This makes it a reliable option for everyday indoor furniture and home improvement projects.

8. BWR (Boiling Water Resistant) Plywood

BWR plywood uses special adhesives that prevent warping and damage in humid or semi-outdoor conditions.

It is suitable for bathrooms, exterior furniture, and areas with frequent moisture exposure. Its durability makes it stronger than standard interior plywood types.

9. Marine Plywood

Marine plywood is made with waterproof glue and high-quality veneers to withstand constant exposure to water. It is ideal for boats, docks, and wet environments.

Its superior bonding and void-free construction provide long-lasting performance in extreme moisture conditions.

10. Film-Faced/Shuttering Plywood

Film-faced plywood is coated with a protective layer that resists water, abrasion, and concrete sticking.

It is mainly used for shuttering and concrete formwork in construction. The smooth coating allows multiple reuses, making it cost-effective for large building projects.

11. Aircraft Plywood

Aircraft plywood is lightweight yet extremely strong, made from high-grade veneers. It is used in aviation, curved furniture, and specialized designs that require flexibility without sacrificing strength.

Its precision manufacturing makes it one of the most premium plywood categories available.

Plywood vs MDF vs Particle Board

These three materials often get confused, but they’re built differently and serve different purposes. Knowing the distinctions helps pick the right one.

| Feature | Plywood | MDF | Particle Board |

|---|---|---|---|

| Construction | Thin wood layers glued together | Fine wood fibers compressed | Wood chips and resin pressed |

| Strength | Strong and durable | Moderate strength | Weakest of the three |

| Moisture Resistance | Good (varies by type) | Poor, swells easily | Very poor, absorbs water |

| Weight | Moderate | Heavy | Lightweight |

| Surface Finish | Visible grain, may need sanding | Smooth, paint-ready | Rough, needs veneer or laminate |

| Cost | Higher | Moderate | Lowest |

| Best For | Furniture, cabinets, structures | Painted furniture, shelving | Budget projects, temporary use |

How Can You Tell the Plywood Quality

Spotting quality plywood isn’t guesswork. A few simple checks reveal whether a sheet is worth buying or best left on the rack.

- Surface Smoothness: Run fingers across both sides. Quality plywood feels even, without rough patches or splinters sticking out.

- Layer Count: More layers usually mean better strength. Check the edges to see how many plies are stacked together.

- Wood Grain Consistency: Look at the face veneer. Uniform grain patterns indicate careful manufacturing and higher quality.

- Core Gaps: Peek at the edges. Quality sheets have tightly packed cores with minimal gaps between layers.

- Weight: Heavier plywood often signals denser wood and better construction. Lift a corner to get a sense of it.

- Edge Finishing: Clean, straight edges without chipping or peeling show attention to detail during production.

- Moisture Content: Quality plywood feels dry, not damp. Excess moisture leads to warping and mold problems later.

Final Thought

Selecting plywood doesn’t have to be complicated anymore. Each type serves a purpose, and knowing the differences saves time and money.

Quality markers help separate good sheets from bad ones, making shopping trips less stressful.

Now it’s time to put this knowledge to work. Head to the store with confidence, check those quality signs, and pick the plywood that matches the project.

Got questions or tips about plywood selection? Drop them in the comments below. Others might benefit from those experiences, too.