Most homeowners walk past drywall every single day without giving it a second thought.

This humble building material is actually a carefully engineered product that’s been protecting homes for over a century.

The composition of drywall affects everything from fire resistance to moisture tolerance, and different varieties serve different purposes. Knowing these differences helps homeowners make smarter decisions and avoid costly mistakes.

This article breaks down the core materials in drywall and explains the main varieties available, so readers can understand exactly what goes on their walls.

What is Drywall?

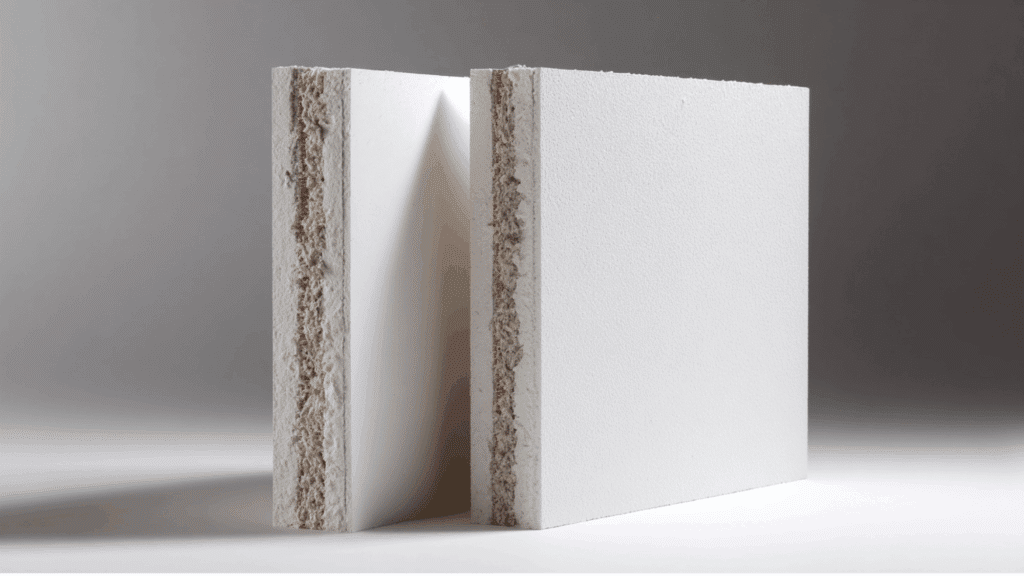

Drywall is a flat panel made primarily of gypsum plaster sandwiched between two thick sheets of paper. It’s the go-to material for creating interior walls and ceilings in most modern buildings.

Some folks call it gypsum board, wallboard, or even Sheetrock, though that last one’s actually a brand name that stuck around.

The beauty of drywall lies in its simplicity and efficiency. Contractors can install it quickly, and it creates smooth, paintable surfaces without the mess and time that traditional plaster requires.

It’s been the standard in construction since the 1950s, replacing older methods that took weeks to complete. Today, it’s hard to imagine building without it.

The Materials that Make Up Drywall

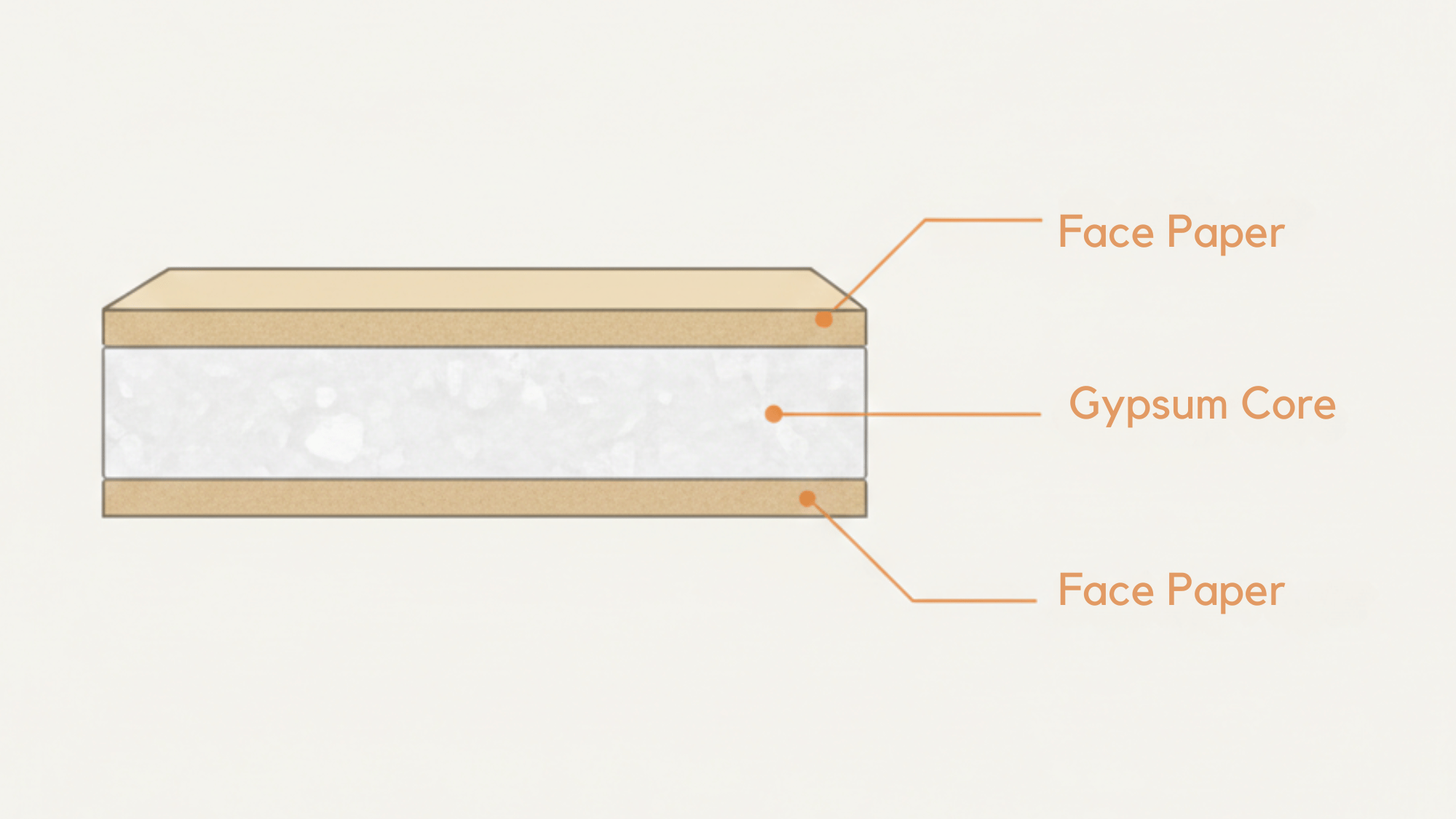

Drywall might look simple, but it’s actually a thoughtful combination of materials working together. Each component plays a specific role in making drywall durable and functional.

1. Gypsum core: The main ingredient, providing fire resistance and structural integrity.

2. Paper facing: Outer layers that create a smooth surface and add strength.

3. Water: Used to activate and bind the gypsum during manufacturing.

4. Additives: Various compounds that enhance specific properties like mold resistance or fire protection.

5. Fiberglass mesh: Sometimes embedded for extra durability in specialized boards.

6. Foaming agents: Help create a lighter, more workable product.

7. Starch: Acts as a binder between the gypsum core and paper layers.

What are the Benefits of Drywall?

Drywall has dominated the construction industry for decades, and that’s no accident. It offers a combination of practical benefits that builders and homeowners simply can’t ignore.

- Convenience: Easy to transport, handle, and work with compared to traditional plaster methods.

- Speed of installation: Contractors can finish walls in days rather than weeks, cutting labor costs significantly.

- Cost-effectiveness: One of the most affordable wall materials available, making it budget-friendly for projects of all sizes.

- Fire resistance: Gypsum naturally resists flames, providing crucial protection and meeting building codes.

- Versatility: Works for walls, ceilings, curved surfaces, and comes in varieties for every specific need.

Drywall Types and Their Specialty Materials

Drywall comes in various types, each designed with specialty materials to meet specific needs. Choosing the right type depends on where it’ll be installed and what challenges it needs to handle.

1. Regular Drywall

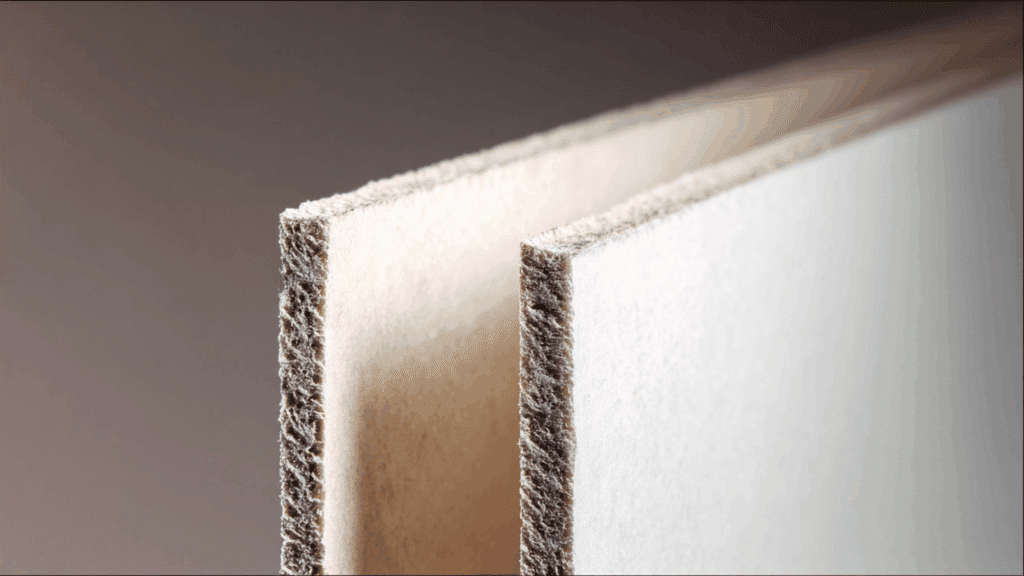

This is the standard drywall found in most homes. It’s made primarily of gypsum sandwiched between paper layers, with a standard thickness of ½ inch for residential use.

Regular drywall works perfectly fine for general wall and ceiling construction in dry, low-traffic areas. It’s the most affordable option and easiest to find.

However, it doesn’t offer special protection against moisture, fire, or impact, so it’s best suited for bedrooms, living rooms, and hallways where conditions stay pretty normal.

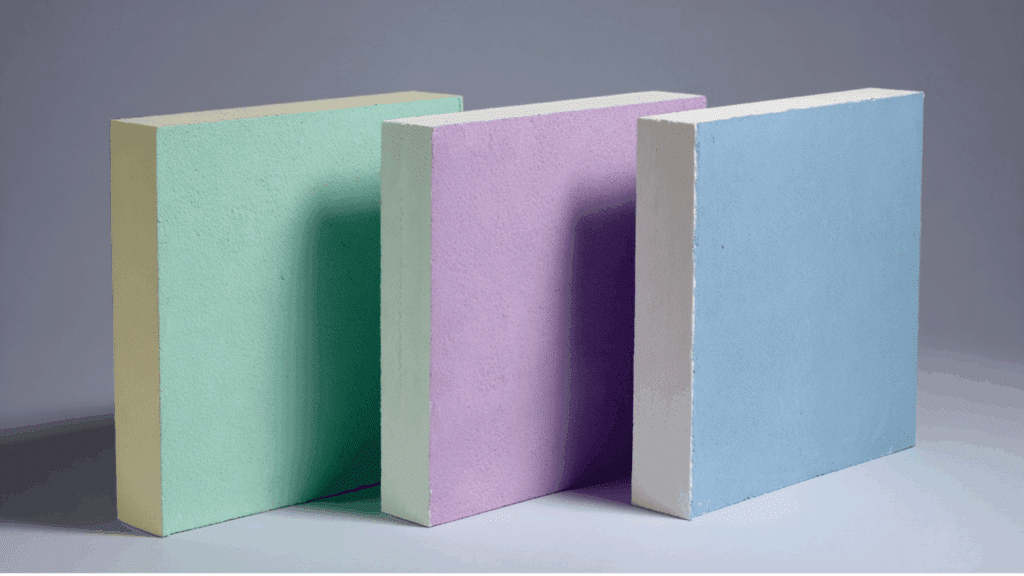

2. Mold-Resistant Drywall (Green Board, Purple Board, Blue Board)

These boards tackle moisture problems head-on. Green Board features a gypsum core with moisture-repellent additives and thicker green paper coated in wax, making it suitable for bathrooms and kitchens.

Purple Board goes further, offering moisture, mold, and mildew resistance while also being scratch and dent-resistant for high-traffic areas.

Blue Board comes faced with blue paper designed for veneer plaster and works well in wet areas, though it’s not completely waterproof. All three use specialty materials like mold-resistant paper and treated gypsum cores.

3. Fire-Resistant Drywall (Type X, Type C)

When fire safety matters most, these are the boards to use. Type X contains special glass fibers in its gypsum core to slow fire spread and is typically 5/8 inch thick, offering one-hour fire resistance.

Type C takes it up a notch with more glass fibers and vermiculite added, providing stronger fire resistance and better dimensional stability during fires.

Both types use noncombustible fibers and reinforced gypsum cores with fire-retardant additives. They’re commonly required by building codes in garages and between units.

4. Cement Board

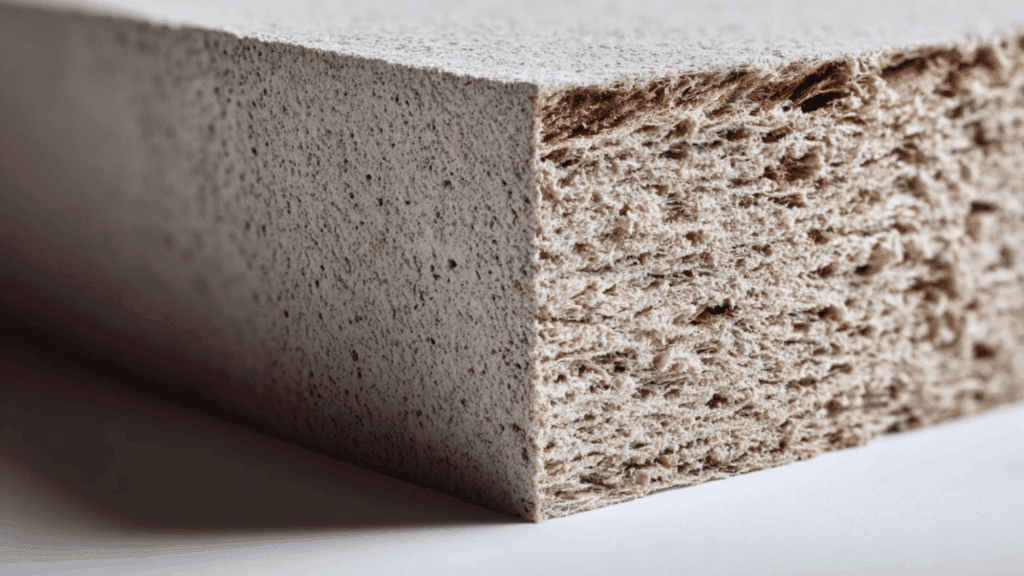

This heavyweight option is composed of cement, sand, and cellulose fibers, making it highly durable and completely moisture-resistant.

Cement board is the go-to substrate for tile in showers and baths because water can’t damage it. The fiber reinforcement increases rigidity and stability, so it won’t flex or deteriorate even with constant water exposure.

It’s heavier and harder to cut than regular drywall, but that durability makes it worth the extra effort in wet environments where standard drywall would eventually fail.

5. Solid Drywall (Fibre Cement Board)

This board features a dense cement core with cellulose fibers and is designed for environments needing superior strength.

It’s built for high-impact, high-traffic areas where regular drywall would get destroyed quickly. The material resists moisture exceptionally well and even stands up to pests like termites.

Commercial buildings, schools, and industrial spaces often rely on solid drywall because it can take a beating and keep on performing. It’s overkill for most homes, but it’s perfect where durability absolutely can’t be compromised.

Drywall Comparison to Traditional Wall Construction Materials

Before drywall became the standard, builders relied on various traditional methods. Each approach had its own strengths and weaknesses compared to modern drywall systems.

| Material | Installation Time | Cost | Durability | Best Use |

|---|---|---|---|---|

| Drywall | Fast (days) | Low | Moderate | Modern homes, quick builds |

| Plaster | Slow (weeks) | High | Very high | Historic homes, luxury finishes |

| Wood Paneling | Moderate | Moderate to high | High | Rustic or traditional aesthetics |

| Brick | Slow | Very high | Extremely high | Exterior walls, industrial style |

| Concrete Block | Moderate to slow | High | Extremely high | Basements, commercial buildings |

| Lath and Plaster | Very slow | Very high | Very high | Historic restoration projects |

To Conclude

Drywall’s composition tells the story of smart engineering. That gypsum core sandwiched between paper might seem basic, but it’s exactly what modern construction needs: affordable, quick to install, and remarkably safe.

The variety of specialized types means there’s a perfect match for practically any situation, from steamy bathrooms to fire-rated garages.

Understanding these materials helps homeowners make informed choices during renovations or repairs.

Next time someone patches a hole or plans a remodel, they’ll know exactly what they’re working with.