Have you measured your truck’s bolt pattern lately?

Getting wheels for your truck isn’t simple.

I know the frustration of ordering a set of wheels, waiting for delivery, and finding out they don’t fit.

I’ve seen folks lose money and time because they didn’t know their exact bolt pattern measurements.

Here’s the good news: I’ll show you why the 8×170 bolt pattern matters for your truck.

After fitting wheels for over a decade, I can tell you which trucks use this pattern, how to check if it’s right for yours, and what you need to know before buying new wheels: no more costly mistakes or wasted weekends.

Understanding 8×170 Bolt Pattern & Its Measurements

What Does The 8×170 Bolt Pattern Mean?

When I talk about an 8×170 bolt pattern, I’m referring to two key numbers.

The “8” indicates the number of lug holes on your wheel, while “170” shows the diameter in millimeters of the circle these holes form.

Think of it like this: if you drew a line through the center of each lug hole, you’d create a circle that’s 170mm across.

You might also see this written as 8 x 6.69 inches – they’re the same measurement, just using different units.

How To Measure A Bolt Pattern Accurately

To measure your bolt pattern, you’ll need:

- A measuring tape or caliper

- A piece of paper and pencil

- Good lighting

For 8-lug patterns, measure from the center of one lug hole to the center of the hole opposite it (across the hub center). This gives you the most accurate measurement.

Common Dimensions Of 8×170 Bolt Pattern

| Measurement Type | Value (mm/inches) |

|---|---|

| Bolt Circle Diameter | 170 mm |

| Number of Lug Holes | 8 |

| Typical Lug Size | M14 or M16 |

| Hub Bore Size (varies) | 124.9 mm (Ford F-Series) |

Compatibility With Hubs

The bolt pattern must match your vehicle’s hub exactly. Even a few millimeters off means your wheels won’t fit properly.

For example, without special adapters, you can’t use an 8×165 wheel on an 8×170 hub.

Factors To Consider When Selecting Wheels With An 8×170 Bolt Pattern

1. Material And Durability Of The Wheels

I always tell my customers that selecting the right wheel goes beyond matching the bolt pattern.

The material of your truck’s wheels affects its performance and longevity.

Steel wheels offer strength at a lower cost, while aluminum alloy wheels combine durability with less weight.

2. Offset And Backspacing Considerations

Offset is key for proper wheel fit. It’s the distance between your wheel’s centerline and where it mounts to the hub. I measure this to ensure:

- The wheel sits correctly in the wheel well

- There’s no rubbing against suspension parts

- Your truck maintains proper handling

Before buying, you’ll need both the offset and backspacing numbers. For 8×170 patterns, typical backspacing ranges vary based on your truck model and tire size.

3. Proper Load Capacity

Load capacity isn’t optional – it’s vital. Here’s what I check:

- Your truck’s gross vehicle weight rating (GVWR)

- The maximum load rating per wheel

- The combined load capacity of all wheels

I suggest picking wheels rated above your needs. This gives you a safety margin, especially for work trucks or heavy hauling.

How To Install Wheels With An 8×170 Bolt Pattern

Safety must be your top priority when installing wheels with an 8×170 bolt pattern.

You’ll need a torque wrench, floor jack, jack stands, socket set, wheel chocks, and work gloves.

Keep a wire brush and tire pressure gauge nearby. Park your truck on flat ground, engage the parking brake, and chock the wheels.

Before lifting your truck, break loose the lug nuts. After securing it on the jack stands, remove the old wheel and clean the hub surface well.

Mount the new wheel and hand-tighten the lug nuts in a star pattern.

Lower the truck until the tires touch the ground. Torque the lug nuts in three passes using a star pattern: start at half spec, move to three-quarters, and finish at full torque.

Check that the wheel sits flush with no gaps. Set proper tire pressure and inspect for any rubbing. Remember to re-check torque after 50-100 miles of driving.

Torque Specifications For Common Vehicles

| Vehicle Model | Torque Spec (ft-lbs) |

|---|---|

| Ford F-250 (2015) | 150-165 ft-lbs |

| Ford Excursion (2004) | 140-160 ft-lbs |

| Custom Vehicles | Refer to manufacturer |

Common Mistakes To Avoid During Installation

The price of getting it wrong isn’t small.

Based on repair shop data, fixing wheel installation mistakes typically costs between $200 to $500.

In severe cases involving bent rims or damaged hubs, repairs can exceed $1,000.

1. Skipping The Torque Specification Check

Many truck owners think tight means right – it doesn’t. Each truck needs specific torque settings:

- Ford F-250 Super Duty: 140-150 ft-lbs

- Dodge Ram 2500: 130-140 ft-lbs

- Chevy Silverado 2500HD: 140 ft-lbs

Under-torquing causes wheels to loosen while over-torquing can stretch or break wheel studs.

Always check your manual for the right specs.

2. Using Incorrect Lug Nuts

Not all lug nuts work with all wheels. Some common mistakes include:

- Using short lug nuts with thick aftermarket wheels

- Mixing cone seat lugs with flat seat wheels

- Installing chrome lugs on black wheels (different seat angles)

3. Hub-Centric vs. Lug-Centric Confusion

Hub-centric wheels center on the hub. Lug-centric wheels center on the lug nuts. Using the wrong type can cause:

- Poor wheel balance

- Shaking at highway speeds

- Uneven tire wear

Always match your wheel type to your truck’s design. This will keep you safe and extend the life of your wheels.

Applications Of The 8×170 Bolt Pattern In Different Vehicles

Trucks And SUVs Using This Pattern

Based on my experience at the wheel shop, the 8×170 pattern shows up most often in heavy-duty trucks. Ford made this pattern standard for their Super Duty trucks in 1999. Here’s what I see daily:

Primary Users:

- Ford F-250 to F-550 (1999-present)

- Ford Excursion (1999-2005)

- Ford E-Series vans (1999-present)

Specialty And Off-Road Applications

The 8×170 pattern works well for custom builds, too. I’ve helped fit these wheels on:

- Modified work trucks

- Off-road project vehicles

- Custom hauling rigs

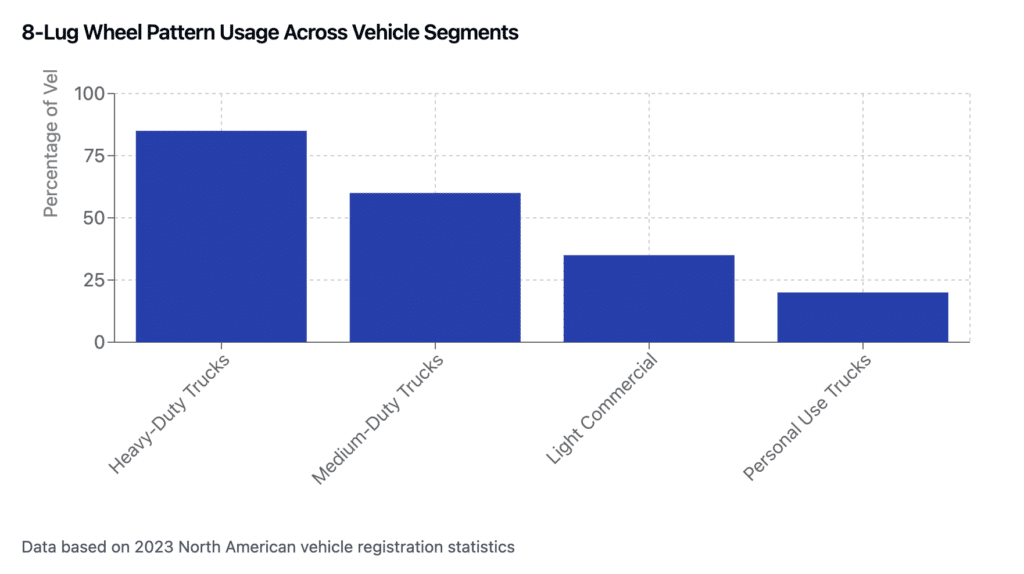

Why Heavy-Duty Vehicles Choose 8×170

The 8-lug design isn’t random. It offers:

- Better weight distribution

- Stronger hold under heavy loads

- More stability for large vehicles

A real-world example: A Ford F-350 dually can handle up to 7,850 pounds of cargo.

The 8×170 bolt pattern helps support this weight while keeping the wheels secure. Over 6 million trucks have been equipped with this bolt pattern since 1999.

It’s a proven design that performs well under tough conditions.

Benefits Of The 8×170 Bolt Pattern

Load-Carrying Capacity

- Spreads weight across 8 points instead of 6

- Supports up to 7,850 pounds per axle

- Reduces stress on each lug nut, enhancing longevity

Better Stability

- Less wheel movement with more attachment points

- Improved braking response for heavy-duty use

- Steadier handling, especially with heavy loads

Durability

- Minimizes wear on individual lug nuts

- Ensures stronger overall attachment

- Extends the service life of wheels and hubs

Terrain Handling

- Performs well across:

- Construction sites

- Farm work

- Mountain driving

- Highway hauling

List Of Vehicles Using 8×170 Bolt Pattern

| Category | Vehicle Models | Years |

|---|---|---|

| Ford Heavy-Duty Trucks | F-250 Super Duty, F-350 Super Duty, F-450 Super Duty, F-550 Super Duty | 1999-Present |

| Ford Vans | E-250, E-350, E-450 | 1999-Present |

| Ford Special Models | Ford Excursion, F-650, F-750 | 1999-2005, 2000-Now |

| International | CXT, RXT, MXT | 2004-2008, 2006-2008, 2005-2007 |

| Custom Applications | Modified military vehicles, specialized work trucks, custom hauling rigs, racing support vehicles | Varies |

What makes this pattern special?

It’s been trusted for 25+ years. Any truck using this pattern is built to handle serious work.

Most of these vehicles stay in service for 200,000+ miles, often longer, with good maintenance.

Conclusion

The 8×170 bolt pattern is a trusted standard in heavy-duty trucks and vans. After looking at every aspect, from proper installation to vehicle fits, it’s clear why this pattern remains popular in the truck world.

Remember three key points when working with 8×170 wheels: always check your torque specs, use the right lug nuts, and ensure proper wheel centering. These steps keep you safe and your truck running strong.

Truck owners who are still unsure about their bolt pattern should take five minutes to measure or ask a wheel professional.

This small effort saves time and money. If you need more help, check your owner’s manual or visit a wheel shop.

Getting it right the first time means your truck stays ready for work or play.