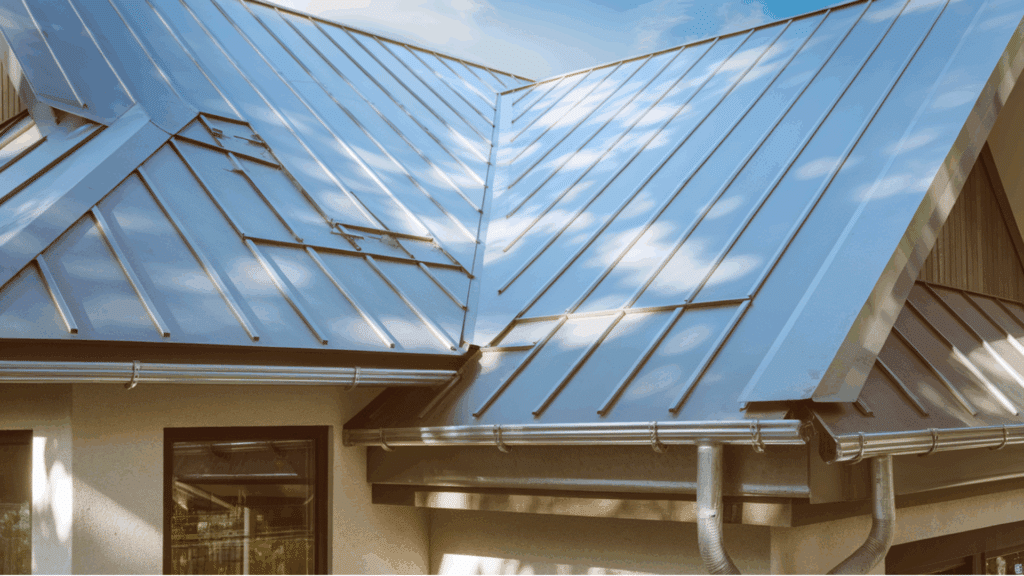

When I first installed a metal roof on my house, I was excited about the sleek, modern look it would give my home. However, as time passed, I noticed something I hadn’t expected: oil canning.

It’s a visual distortion that causes the panels to ripple or wave slightly, and while it doesn’t affect the roof’s performance, it’s certainly not something you want to see.

I wasn’t alone in this; oil canning is quite common on metal roofs. I’m here to share what I’ve learned through the process: why it happens, how to spot it, and most importantly, how to prevent it.

Trust me, addressing this issue promptly can save you a great deal of frustration.

What Is Oil Canning In Metal Roofing?

Oil canning in metal roofing is a subtle flaw that can spoil the look of an otherwise perfect roof. It appears as wave-like ripples, especially on long, flat metal panels.

While it doesn’t affect the roof’s strength or performance, it can be an eyesore. Common causes include metal gauge, temperature changes, and improper installation.

Though it’s mostly a visual issue, it still matters; first impressions count, especially when it comes to your home.

Signs of Oil Canning

- Oil canning is often subtle: You might not notice it unless you’re really looking for it.

- Once you see it, it stands out: Ripples, waves, or slight bulges can appear across the metal panels.

- Lighting plays a big role: It’s most noticeable in bright sunlight or when viewed from certain angles.

- Shadows highlight the flaws: Light casts across the metal, bringing out the uneven surface.

- Watch for visual clues: These signs are often the first indication that oil canning is present.

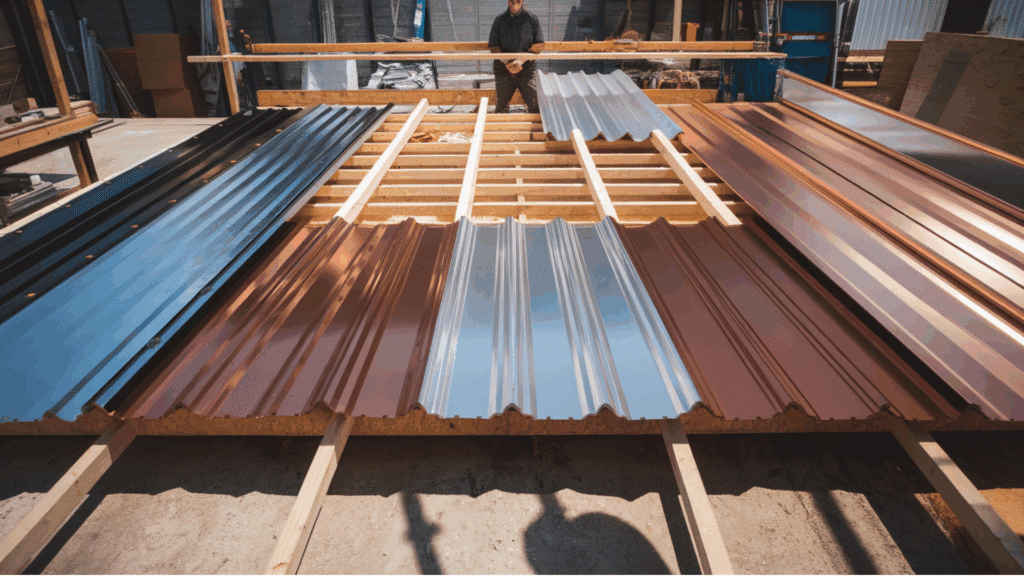

Types of Metal Roofing Materials

If you think the material you choose for your roof doesn’t matter when it comes to oil canning, think again. Trust me, the right material can mean the difference between a smooth, modern roof and one with annoying ripples.

- Steel: Great for durability, but can be prone to oil canning if it’s on the thinner side.

- Aluminum: More flexible, but as I found out, it can warp easily if not installed correctly.

- Copper: Copper is more resistant to oil canning due to its malleability, but it can still occur if the installation isn’t top-notch.

- Galvalume: This material provides enhanced protection against oil canning, particularly when thicker panels are selected.

Why Does Oil Canning Occur?

Understanding oil canning is key to preventing it. When I installed my roof, I saw how material, installation, and weather all play a part. It’s like baking; a small mistake can ruin the whole result.

1. Material-Related Causes

The metal roofing material you choose plays a significant role in whether oil canning becomes an issue.

I found that thin-gauge metal is far more likely to exhibit signs of distortion, especially when subjected to pressure or temperature fluctuations.

2. Thin Gauge Metal

When I first researched my metal roofing options, I didn’t pay as much attention to the gauge or thickness of the material.

I learned the hard way that thinner panels are more prone to bending and warping, which eventually led to oil canning.

Using a thicker gauge can make a significant difference in keeping your roof level.

3. Type of Metal

Aluminum, while lighter, tends to be more flexible than steel. Although it may seem like a suitable option, I found it to be more prone to warping.

Steel, on the other hand, is stronger but requires proper installation to avoid oil canning.

The key is choosing the right material based on your climate and installation plan.

4. Installation-Related Causes

Sometimes, oil canning is the result of poor installation. It’s like assembling a piece of furniture; the instructions have to be followed to get everything aligned properly.

If not, you might end up with irregular panels or even some unwanted distortions.

5. Incorrect Fastening

Proper fastening is critical to prevent oil canning. If fasteners are too tight, they can create tension in the metal, leading to distortion.

However, if they’re too loose, the panels can shift, resulting in those unwanted ripples. It’s about finding that ideal balance, and trust me, it’s worth the time to get it right.

6. Improper Alignment

Another important factor I learned was alignment. Misaligned panels tend to create irregular pressure, which, in my case, led to those annoying distortions.

Ensuring everything is aligned correctly during installation is crucial to maintaining a level roof.

7. Lack of Support

Another key takeaway from my own experience is that metal panels require substantial support to remain rigid. Without it, they’ll sag and warp over time.

Proper structural support beneath the panels is essential for keeping the roof from developing those annoying distortions.

How to Identify Oil Canning Early

Catching oil canning early means you can prevent it from becoming a larger problem later. I’ve been there, and I can tell you that identifying the issue early helps you take action before it becomes too evident.

Key Indicators of Oil Canning

Look for subtle waves or ripples in the roof, especially when the light hits it at certain angles. The ripples might not be noticeable, but once you spot them, they’re hard to ignore.

If you have a ladder handy, get up close and inspect the flat sections of your roof for any visible distortion.

Oil Canning vs. Other Roof Defects

It’s essential to understand that oil canning is distinct from more severe issues, such as sagging or buckling. Oil canning doesn’t compromise your roof’s function; it’s mostly a cosmetic issue.

On the other hand, issues such as sagging or buckling typically indicate more significant structural problems. Knowing the difference will help you address the problem correctly.

When to Seek Professional Help

If you notice the oil canning getting worse or if you’re unsure about how to fix it, don’t hesitate to call in a roofing professional.

I reached out to an expert when I wasn’t sure how to handle my roof, and it was the optimal decision. They helped me understand what was happening and provided solutions to fix the problem.

Preventive Measures to Avoid Oil Canning

The key to avoiding oil canning? Prevent it from happening in the first place. I’ve learned that a little extra effort up front can save you a lot of trouble down the road.

1. Proper Material Selection

I can’t emphasize this enough: selecting the right material is one of the most critical steps. Opt for thicker panels and avoid low-quality metal.

The higher the quality of the material, the less likely you are to experience oil canning.

2. Correct Installation Techniques

Ensure the panels are installed with proper alignment and the correct fasteners.

I took extra time during the installation to ensure everything was properly aligned and tightened to the correct tension, and it paid off in the long run.

It’s worth investing in an experienced installer if you’re not doing it yourself.

3. Design Considerations

The design of your roof can help minimize oil canning. Factors such as roof slope, panel widths, and overall geometry all contribute to how the roof performs under pressure.

A well-designed roof can handle thermal expansion and contraction more effectively, reducing the risk of oil canning.

4. Environmental Adaptation

Temperature changes can exacerbate oil canning, but with proper insulation and ventilation, you can help manage thermal expansion.

I added extra insulation to my roof to help it handle fluctuating temperatures, and it made a clear difference in keeping things even.

Conclusion

Looking back on my experience with oil canning, I wish I had paid more attention to the finer details earlier on.

However, I learned a great deal through the process, and now I know how to prevent it from becoming a problem in the future.

If you’re installing a metal roof or already have one, don’t let oil canning sneak up on you.

With the right materials, installation, and a little planning, you can keep your roof looking great and free of those frustrating distortions.

Please don’t wait until it’s too late, take action now to keep your roof in excellent condition!