Are you planning to install a metal roof and worried about making costly mistakes? You’re not alone.

Many homeowners and contractors face challenges during metal roof installations, and these mistakes can lead to costly repairs.

Understanding these common errors and how to avoid them is essential for a smooth, long-lasting installation.

In this blog, I’ll walk you through some of the most frequent installation mistakes and share practical tips to prevent them.

I’ll also cover key topics like choosing the right metal roof for your home and how to spot installation issues early, two important steps to ensure the longevity and security of your roof.

Let’s get started!

Metal Roof Installation Mistakes to Avoid

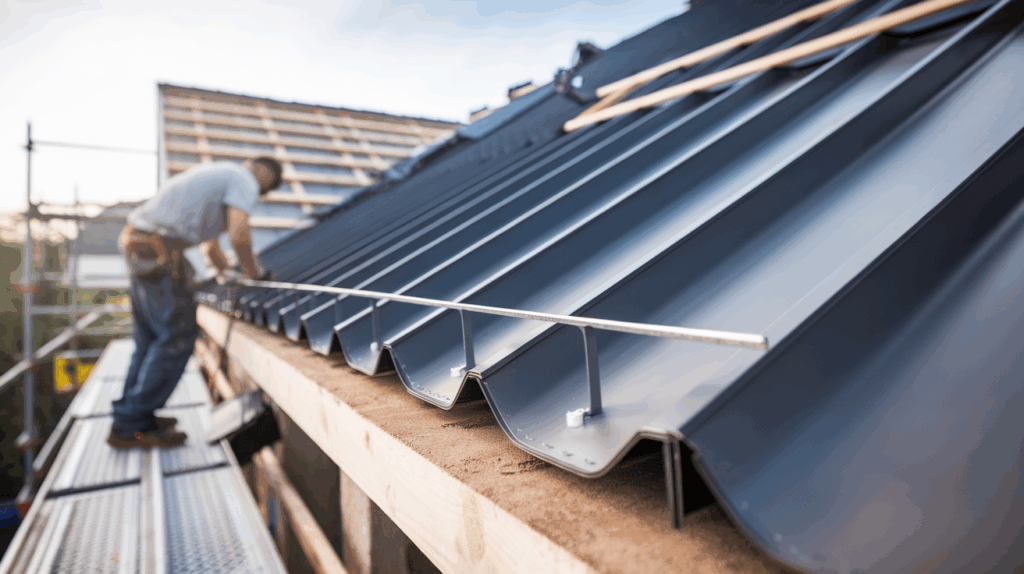

Installing a metal roof is a great way to protect your home, but it’s important to get it right. Even small mistakes can lead to leaks, costly repairs, and a shorter roof lifespan.

1. Improper Measurements

A common mistake in metal roof installation is incorrect measurements. If the panels aren’t measured properly, they may not fit, causing gaps, misalignment, or requiring extra cuts.

This leads to wasted materials and more time spent fixing the problem.

How to Avoid It: Measure your roof accurately before buying metal panels. Use a tape measure, double-check the length and width, and use a chalk line for straight cuts. Measure twice to avoid mistakes.

2. Neglecting Proper Roof Ventilation

Without proper ventilation, moisture can accumulate in the attic and under the roof, creating an environment where mold, mildew, and rust grow.

This excess moisture can also lead to condensation, which causes wood rot and weakens the structural integrity of your roof. Over time, this significantly shortens your roof’s lifespan.

How to Avoid It: Install ridge, soffit, or gable vents to ensure proper roof ventilation. This helps control moisture levels. Check ventilation requirements based on your roofing materials and local climate.

3. Not Using the Right Fasteners

Using the wrong fasteners, like regular nails instead of specialized screws, can cause serious problems.

Over time, the roof may loosen, leading to leaks, and metal panels might shift or even blow off during storms. Always use the correct fasteners to ensure a secure and durable installation.

How to Avoid It: Use fasteners designed for metal roofing, like stainless steel or coated galvanized screws, as they resist rust and weather. Ensure fasteners securely penetrate the underlying wood to prevent loosening.

4. Improper Overlapping of Panels

Proper overlaps are crucial when installing metal roof panels. If the panels don’t overlap enough, water can seep through the seams, leading to leaks.

Incorrect overlaps also compromise the roof’s overall integrity, making it more vulnerable to damage over time.

How to Avoid It: Follow the manufacturer’s guidelines for panel overlap, typically 1.5 to 2 inches, to ensure proper water runoff and prevent gaps. Secure panels at each overlap to avoid wind lift.

5. Ignoring Expansion and Contraction

Metal expands and contracts with temperature changes. Without allowing space for this natural movement, the panels can buckle, warp, or cause the fasteners to loosen.

This can lead to premature wear and tear, reducing the roof’s lifespan and compromising its performance.

How to Avoid It: Leave space between panels for thermal expansion. Use snug, not overtightened, fasteners to allow movement without compromising the roof.

6. Not Sealing the Edges Properly

Sealing the edges and seams is crucial for creating a waterproof barrier. If left unsealed, moisture can seep under the panels, leading to rust, mold, and leaks.

Proper sealing prevents water infiltration, protects vulnerable points, and ensures the roof stays secure against wind and shifting. Use high-quality sealant to maintain a durable, leak-free roof.

How to Avoid It: Use high-quality roofing sealant around edges, seams, and fasteners. Ensure each panel joint is sealed with waterproof sealant or flashing, especially around vents, chimneys, and valleys where leaks are more likely.

7. Installing the Metal Roof During Poor Weather

Installing a metal roof in bad weather, like rain, snow, or high winds, can cause several issues.

Wet panels become slippery, making the installation hazardous, while water exposure can lead to rusting. It’s best to wait for clear weather to ensure safety and avoid damage to the roof.

How to Avoid It: Install the roof during dry, calm weather, preferably on a sunny day. Avoid rainy, windy, or icy conditions to prevent rust and ensure safe handling of panels.

8. Not Considering the Roof Pitch

The roof pitch, or slope, is essential for proper drainage. On low-pitched roofs, the angle is too shallow to allow water to flow off easily, which can cause water to pool on the surface.

This pooling water creates extra weight, putting unnecessary stress on the roofing material. Over time, the trapped moisture can seep into seams or joints, leading to leaks.

How to Avoid It: For low-slope roofs, follow the manufacturer’s guidelines for installation. Adding underlayment or extra sealing can improve water drainage, and for very shallow pitches, consider additional drainage systems.

9. Using the Wrong Underlayment

Underlayment acts as a moisture barrier to protect against leaks. Using the wrong type, like one not designed for metal roofs, can lead to trapped moisture, rust, and early deterioration.

Metal roofs need specific underlayment, such as synthetic or waterproof felt, to maintain effectiveness and longevity.

How to Avoid It: Use metal roofing-specific underlayment, like synthetic or felt with a waterproof layer. Avoid asphalt-saturated felt and follow the manufacturer’s specifications.

10. Forgetting to Protect the Roof During Installation

Metal roofing panels are vulnerable to scratches and damage during installation, particularly if dragged across rough surfaces or stacked incorrectly.

Scratches can impact the roof’s appearance and damage the protective coating, potentially leading to rust and a shorter lifespan.

How to Avoid It: Handle panels with care during installation, using padding or tarps to prevent scratches. Use proper lifting equipment to avoid damage, and keep panels protected until fully installed.

11. Skipping the Roof Inspection

Skipping the roof inspection before installation can cause issues like rotting wood, cracks, or weak spots, compromising the roof’s integrity and performance.

These issues may prevent proper installation and could lead to long-term problems like leaks, reduced durability, or even structural failure.

How to Avoid It: Thoroughly inspect the roof before installation, checking for damage like weakened decking or rotting beams. Address any structural issues first to prevent complications during the metal roof installation.

12. Improperly Installed Flashing

Flashing plays a crucial role in preventing leaks at roof joints, particularly around areas like chimneys, vents, and valleys where water is most likely to collect.

It acts as a barrier, directing water away from these vulnerable spots. If the flashing isn’t installed properly, water can seep underneath the metal panels, bypassing the protective layer and causing significant water damage over time.

How to Avoid It: Install flashing around roof penetrations like chimneys and vents, ensuring it fits snugly and directs water away. Use roofing cement or silicone sealant to reinforce the flashing and prevent gaps.

How to Spot Installation Issues Early?

Let’s see some common signs that indicate something may have gone wrong during your metal roof installation:

- Misaligned Panels: Panels that don’t line up correctly can cause gaps, leading to leaks and water damage.

- Loose Fasteners: Fasteners that are too loose can allow panels to shift or lift during windy conditions, compromising the roof’s stability.

- Water Pooling: If you notice water collecting in low-pitched areas, it might mean the roof isn’t draining properly.

- Unsealed Seams: Check seams for gaps or inadequate sealing. This can lead to water seeping in, causing rust or mold.

- Rust Around Fasteners: Rust or corrosion around fasteners indicates moisture buildup, possibly due to improper sealing.

- Uneven or Buckled Panels: If the panels appear uneven or warped, it could signal a problem with the installation process.

Addressing these issues quickly can save you from costly repairs down the line.

Choosing the Right Metal Roof: Standing Seam vs. Corrugated

When selecting a metal roof for your home, it’s important to understand the differences between the two most popular types: standing seam and corrugated.

Standing Seam Metal Roofs

Standing seam metal roofs consist of interlocking panels with raised seams that run vertically from the eaves to the ridge. This design makes them perfect for regions with heavy rainfall, snow, or harsh weather.

The raised seams allow water to flow off easily, preventing pooling and leaks.

| Pros | Cons |

|---|---|

| Durability: Excellent resistance to wind, water, and snow. | Higher Cost: Generally, more expensive due to the complexity of installation and materials. |

| Low Maintenance: Fewer exposed fasteners, reducing the risk of leaks and maintenance needs. | Installation Time: May take longer to install compared to simpler roofing types. |

Best For: Standing seam metal roofs are perfect for areas with extreme weather and homeowners who prefer a long-lasting, low-maintenance roof. They also suit modern or contemporary homes looking for a stylish upgrade.

Corrugated Metal Roofs

Corrugated metal roofs are made of metal panels with a wavy pattern that adds strength and durability while being more affordable than standing seam roofs.

They are often used in agricultural buildings, sheds, and homes in dry climates. However, because they have exposed fasteners, they can be prone to leaks and require more maintenance over time.

| Pros | Cons |

|---|---|

| Affordability: Less expensive compared to standing seam roofs, making it a cost-effective choice. | Higher Maintenance: Exposed fasteners can rust or loosen over time, leading to leaks. |

| Easy to Install: Simple design and installation process. | Less Visual Appeal: Corrugated roofs may not have the sleek, modern look some homeowners prefer. |

Best For: Corrugated metal roofs are best for agricultural buildings, garages, and homes in dry or mild climates. They’re a good choice for budget-conscious homeowners or those looking for an industrial-style roof.

Conclusion

I hope this guide has helped you understand the common mistakes to avoid during your metal roof installation.

I know it can be overwhelming to make sure everything is done right, especially when you’re aiming to protect your home with a durable, long-lasting roof.

By focusing on the details, such as accurate measurements and choosing the right materials, you’ll prevent costly mistakes and ensure your roof is secure and built to last.

Remember, taking the time to get it right now will save you time and money later. Patience and care during the installation process are key.

This isn’t just a roof you’re installing, it’s an investment in the safety and value of your home. If you’re unsure at any stage, don’t hesitate to reach out for professional help.